Commissioning - Page 23

3.6

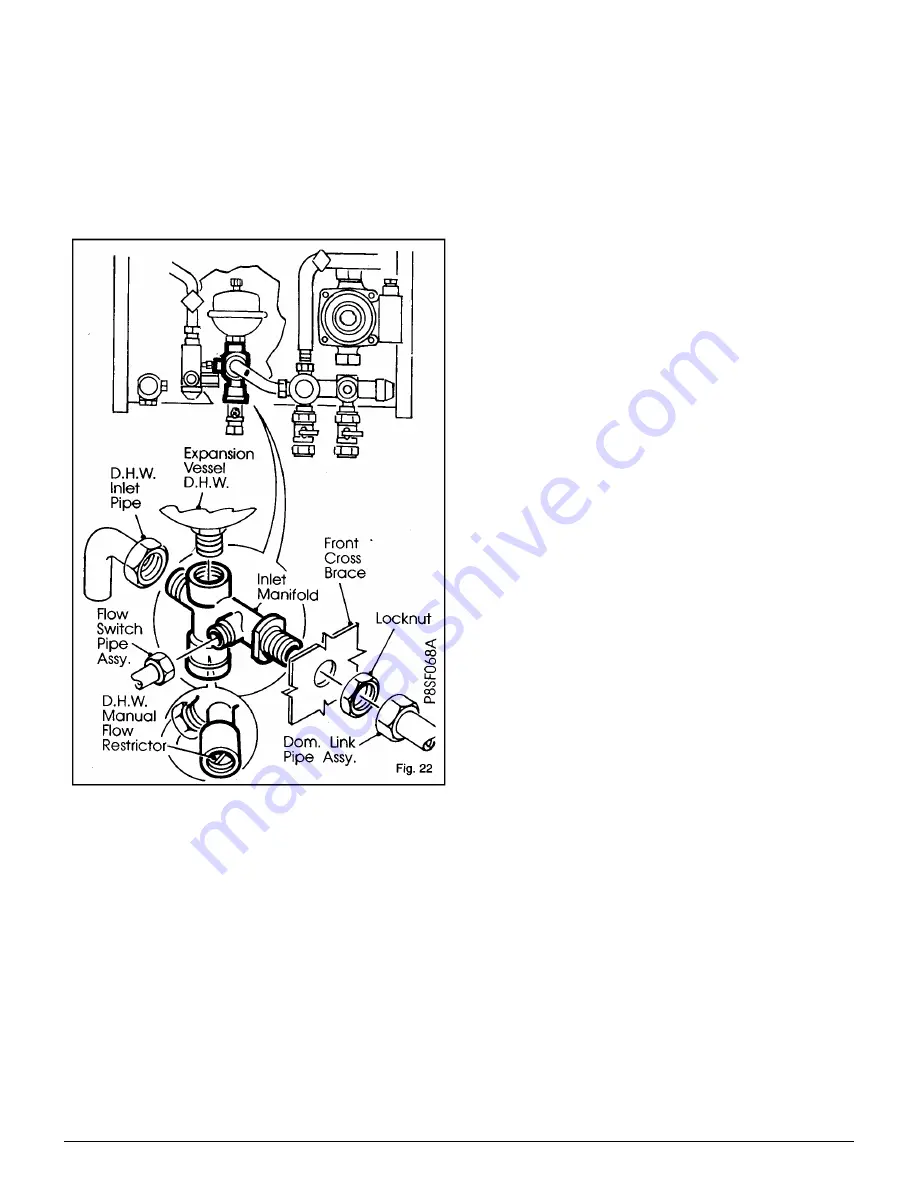

D.H.W Flow Rate

The appliance contains an automatic flow regulator

supplying a nominal flow rate of 12 litres/minute (100 &

100e). These flow rates will give a nominal temperature rise

of 35°C. Should it be desired to set the appliance to give a

higher temperature rise, the flow rate can be further reduced

by using the manual flow restrictor (clockwise to reduce)

located in the manifold below the mini expansion vessel -

Fig. 22.

3.7

Central Heating

a)

Ensure that all external controls such as a timers are

switched On and that room thermostat/s are calling for

heat.

b)

Set the Central Heating switch to Timed (if system fitted

with Timer) or Constant. The appliance will operate in

accordance with the pre-selected temperature set on the

lower temperature control knob.

3.8

Temperature Controls

a)

Central Heating

The lower control knob enables you to control the

temperature of the central heating flow as it leaves the

appliance. This knob can be set between the - and + setting.

The graduations correspond approximately to a temperature

of 60°C to 79°C. Under a minimum load

condition the flow temperature can rise to 87°C at maximum

setting. The appliance is fitted with a Central Heating switch

which will allow you to switch Off the central heating during

the summer months (mid position).

b) Hot Water

The upper control knob enables you to control the

temperature of the domestic hot water as it leaves the

appliance. The knob can be set between the - and + setting.

The graduations - to + correspond approximately to a

temperature of 45°C to 65°C.

3.9

Appliance Protection Devices

Loss of gas supply, flame failure, or over-heating of the

central heating water will cause the appliance to shut down

or Lockout.

On the 100 model (with permanent pilot) this will be

indicated by the pilot being extinguished. To restart the

appliance follow the lighting instructions on the boiler facia

label or as shown in Section 3.3.

On the 100e model (electronic) this will be indicated by the

lockout light being illuminated. To Reset the appliance press

the RESET button on the front panel and hold in that position

for 10 seconds and release. The appliance should now

operate normally.

If this is not the case refer to the Fault Finding guide either

on the rear of the white front case or pages 39 & 48 of these

instructions.

If the central heating system looses pressure for any reason

the appliance will cease to function and the Low System

Pressure light will illuminate. The system and the appliance

should be checked for leaks (including discharge from the

pressure relief pipe). Correct any faults and re-pressurise the

system with reference to Section 1.6. Mains Water Feed

Central Heating.

All models are fitted with a Frost thermostat which will bring

the appliance On when the local temperature around the

appliance falls below 5°C The appliance will shut down when

the temperature of the system water has been raised by

approximately 10°C

The appliance is protected provided the Mains light is

illuminated and the Boiler switch is set to On (and on

permanent pilot models the pilot is alight), irrespective of the

settings of any external controls.

Note:

the Frost thermostat will operate with the central

heating switch in any position therefore when leaving the

property in cold weather for extended periods, the boiler will

be protected even when the switch is set to Off (Mid

position).

Note:

While the appliance is being used to provide hot water

at any draw off point, the central heating will not operate.

When hot water is no longer required the appliance will

automatically revert to central heating.

Summary of Contents for 80e

Page 5: ...Optional Extras Page 5 ...

Page 6: ...Optional Extras Page 6 Installation instructions included as necessary with each kit ...

Page 7: ...Optional Extras Page 7 Installation instructions included as necessary with each kit ...

Page 12: ......

Page 28: ...Routine Maintenance Page 27 ...

Page 30: ...Routine Maintenance Page 29 ...

Page 34: ...Component Replacement Page 33 ...

Page 35: ...Component Replacement Page 34 ...

Page 43: ...7 1 Control Flow Sequence Permanent Pilot Page 42 ...

Page 44: ...7 2 Functional Flow Permanent Pilot Page 43 ...

Page 45: ...7 3 Fault Finding Permanent Pilot Page 44 ...

Page 46: ...7 4 Electrical Diagram Permanent Pilot Page 45 ...

Page 47: ...8 1 Control Flow Sequence Electronic Page 46 ...

Page 48: ...8 2 Functional Flow Electronic Page 47 ...

Page 49: ...8 3 Fault Finding Electronic Page 48 ...

Page 50: ...8 4 Electrical Diagram Electronic Page 49 ...