3.0 Repressurising System

6

© Baxi Heating UK Ltd 2008

bar

0

1

2

3

4

bar

0

1

2

3

4

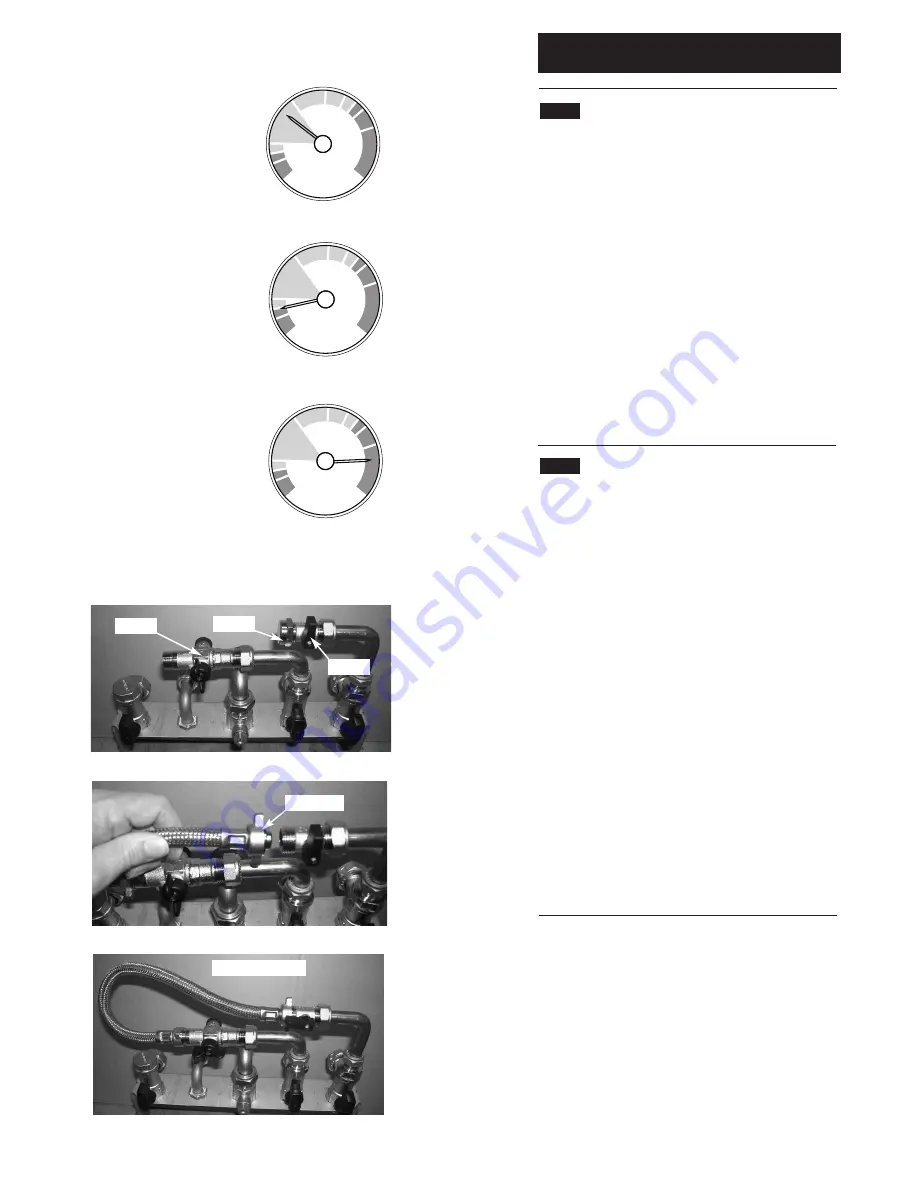

Fig. 1

Fig. 2

Normal Pressure

Requires

Repressurising

Tap

Tap

Cap

Wing Nut

Loop Connected

Boiler Taps &

Connections, as

viewed from

underneath

3.1

Central Heating System Pressure

1. The water pressure in the central heating system is

indicated by the pressure gauge.

2. With the system cold and the boiler not operating the

pressure should be at least 0.5 bar. During operation the

pressure should not exceed 2.5 bar, and will normally be

between 1.0 and 2.0 (Fig. 1).

3. A pressure of 3 or greater indicates a fault. The safety

pressure relief valve will operate, at a pressure of 3 (Fig. 3).

It

is important that your Installer or Service Engineer is

contacted as soon as possible.

4. The minimum pressure for correct operation is 0.5. If the

pressure falls below 0.5, this may indicate a leak on the

central heating system (Fig. 2). Error Code E119 will be

shown on the display.

3.2

To Re-Pressurise the System

(Optional Filling Loop)

1. The procedure is for the optional filling loop kit when

fitted. However, even if your boiler has an external loop, the

principle is similar.

2. Look at the boiler from underneath. There will be two taps

at the end of copper pipes, one with a blanking cap on the

end. Do not operate these taps yet.

3. Your installer will have left a metal braided hose (the ‘filling

loop’) with you for safe keeping.

4. This loop MUST be connected to the taps. Remove the

blanking cap and set aside.

5. Connect the loop to the taps with the wing nuts. These

should be hand tightened.

6. Carefully open the handles on both taps and check the

boiler pressure gauge. Once the needle on the gauge is

above the 0.5 mark both taps can be closed.

7. Undo the two wing nuts, remove the loop and refit the

blanking cap. Put the loop in a safe place for future use.

bar

0

1

2

3

4

Fault

Fig. 3