19

The SUPPLY indicator (green) will remain illuminated all the time the supply is present to the boiler.

The CALL indicator will illuminate (green) on demand from the programmer and thermostats or (red)

for an alarm overheat condition. It will flash (green) for 2 to 3 minutes during which it carries out

self-tests before allowing the boiler to produce heat. At the end of this period it will remain on steady

(green), until the heating demand is satisfied.

The HEAT indicator will illuminate when the boiler actually

produces heat, this is only when the CALL indicator (green) is

steady. The gradual build up in heating power of the boiler can

be seen on the front panel. The HEAT indicator also shows the

boiler modulating when it reaches operating temperature.

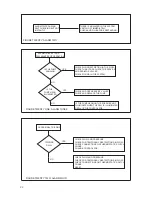

The ALARM indicator flashing (red) will only illuminate if there is

a problem. The HEAT and the CALL (green) indicators will turn

off. The boiler will remain in this tripped state until it is re-set.

To reset an ALARM follow the ‘Alarm Reset’ procedure.

TEMPERATURE CONTROL. The boiler output temperature can be

adjusted from the front panel Minimum setting for C series is

approximately 65

0

C and U series 30

0

C. Maximum setting for C

series is approximately 80

0

C and U series is 60

0

C.

CLEANING.

Use only a damp cloth and mild detergent to clean

the boiler outer casing. Do not use abrasive cleaners. Do not

allow water inside the boiler. Do not immerse in water.

OPERATION & INDICATORS

SERVICING

IT IS ESSENTIAL THAT THE BOILER IS CHECKED ANNUALLY, Checks must include the electrical

connections and inhibitor concentration.

Before any servicing or maintenance is carried out on the system, ensure that the electrical supply

has been disconnected first. Care must also be taken as the water may be scalding hot and at a high

pressure.

Check the main electrical power connections are tight. Loose connections can cause a burning at

the connectors.

Part Locations and comments (see page 2)

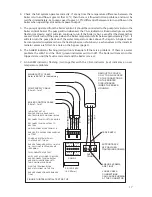

Fuse FS1 is found near the top of the main power PCB assembly.

The temperature switch connected to Conn 3 is situated on the body of the boiler approximately

1/3rd of the distance up from the bottom between insulation and boiler.

The thermistor assembly plugs into the main power PCB assembly through Conn 4, and is clamped

at the top of the boiler. Care must be taken not to break the fine wires.

The control PCB assembly is mounted on the back of the bottom front panel, and plugged into the

main power PCB Conn 2. Great care must be taken when changing this board assembly not to damage

any of the components, especially those adjacent to the mountings.

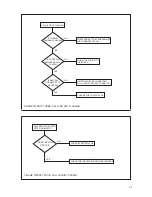

To change the main power PCB, follow ‘Replacing the Main Power PCB’ procedure (see page 20).

Each of the main electrical elements should have a resistance of approximately 19 ohms terminal to

terminal, (red to red, yellow to yellow, blue to blue, and black to black) and an insulation resistance

greater than 2 Meg ohms between terminal and case. If the elements are open circuit terminal

to terminal, or have short circuit insulation resistance terminal to case, then the boiler must be

replaced.

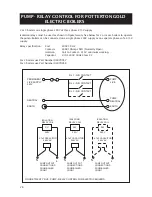

FIGURE FIFTEEN: CONTROL PANEL

Gold

Low

High

Overheat

Boiler ON

Call

Mains ON