14.0

Servicing the Boiler

40

© Baxi Heating UK Limited 2010

14.2

Annual Servicing - Inspection

WARNING: The PCB Control and Fan

Assembly are 325 Vdc. Isolate system

controls before access

1. Ensure that the boiler is cool.

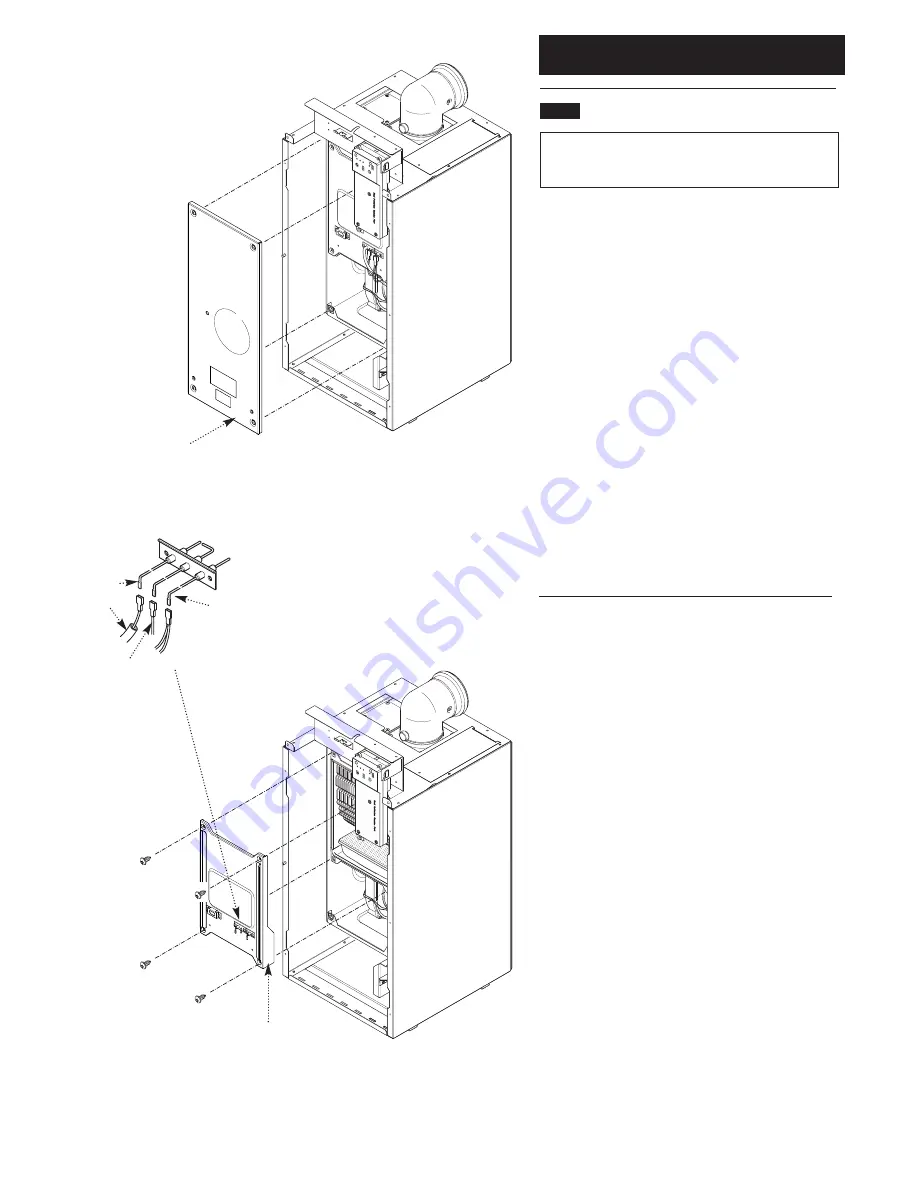

2. Remove the facia and front door panel.

3. Release the four

1

/

4

turn screws securing the air box door

panel and remove the panel (Fig. 39).

4. Disconnect the three leads from the terminals (Fig. 40).

5. Undo the four screws securing the combustion box door

and remove the door (Fig. 41).

6. Visually check for debris/damage and clean or replace if

necessary the following:

a) Burner.

b) Heat exchanger fins.

c) Fan compartment

(Check also for condensate leaks).

d) Insulation.

e) Door seals-

Important:

Pay particular attention to

the condition of the combustion box door seals.

f) Electrodes.

g) The condensate trap.

h) The condensate pump

i) Top of heat exchanger.

Air Box Door Panel

Lead Terminals

Combustion Box

Door Panel

Fig. 39

Fig. 41

Fig. 40

Sensing

Earth

Spark

Sleeve