SECTION 4

POTTERTON COMMERCIAL PRODUCTS DIVISION

INSTALLATION, OPERATION & MAINTENANCE MANUAL

PAGE 12

ISIS HE

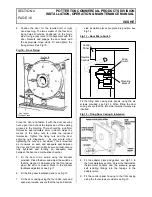

Boiler Erection

Waterway Sealing

The waterway sections are sealed at assembly with

silicone rubber compound (Flytande-Packning 260)

and boiler sealing cement (Brandkitt-1000 Palokitti

1000). The waterway sealing grooves must be

cleaned and primed with the primer liquid before

applying the sealant. The primer must be dry before

applying the sealant.

The silicone rubber compound and boiler sealing

cement are supplied in cartridges which should be

loaded into the sealant gun. The primer liquid is

supplied in a bottle and is applied by hand (see

Fig.4).

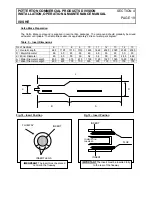

All sealing grooves must be primed and then filled

with the appropriate sealant to form a bead

approximately 5mm (1/4”) proud. This is obtained by

cutting the correct size aperture in the cartridge

nozzle.

If the nozzle is not cut to approximately 5mm (1/4”)

diameter an incorrect amount of sealant will be

applied. When piercing the sealant tube direct the

nozzle away from the face or hands to minimise the

risk of skin contact.

Before commencing sealing operations sealant and

primer must be checked to ensure that there is

sufficient for the sections being erected (see table 4

for specific quantities). It is advisable to keep spare

cartridges to hand if these are available, particularly

for the boiler cement as some cartridges may contain

a certain percentage of water, which should be safely

drained off before use.

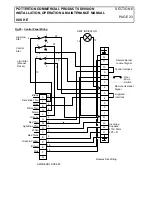

The sealants and sealant gun, which are supplied

with the boiler, are classified as consumables. In

addition to this items standard boiler erection tools

will be required. These should include a crowbar,

heavy duty adjustable wrench and a jack for raising

the firing door.

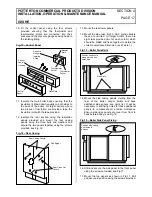

Erection procedure

Waterway Sections

1. Check off all materials and parts against the

delivery document and boiler parts list (Section 7)

ensuring that a sealant gun and adequate supply

of sealants and primer have been provided.

2. Using a clean rag and paraffin, clean the ‘O’ ring

grooves and sockets on the rear waterway

section.

3. Clean all sealing grooves with a wire brush and

apply the primer liquid using the applicator bottle

provided. Allow the primer to dry. This is

important otherwise the sealant may not stick.

4. Apply a coating of silicone rubber compound

5mm (1/4”) proud around each of the two outer

boiler sealing grooves. See Fig.5

5. Apply a liberal coating of boiler sealing cement

around the inner sealing groove.

6. Support the rear section in its correct position on

the boiler base.

WARNING: THE SECTIONS ARE NOT SELF-

SUPPORTING UNTIL SEVERAL SECTIONS HAVE

BEEN ASSEMBLED TOGETHER. THEREFORE

WHEN STARTING TO BUILD THE BOILER THE

REAR SECTION AND ADJACENT INTERMEDIATE

SECTIONS SHOULD BE ADEQUATLEY

SUPPORTED TO PREVENT INJURY OR DAMAGE.

DUE TO THE WEIGHT OF THE SECTIONS

ASSEMBLY SHOULD BE PERFORMED BY NO

LESS THAN TWO OPERATIVES.

Summary of Contents for Isis HE

Page 1: ...MAY 2004 ...