POTTERTON COMMERCIAL PRODUCTS DIVISION

SECTION 4

INSTALLATION, OPERATION & MAINTENANCE MANUAL

PAGE 15

ISIS HE

6. Open the drain-cock and drain the boiler.

Remove the blanking plates. Connect the flow

and return 3” – 4” BSP extension turrets to the

boiler (8 – 14 Section only).

Boiler Dismantling

IMPORTANT: THE BOILER SECTIONS ARE NOT

SELF SUPPORTING PARTICULARLY WHEN

THERE ARE ONLY TWO OR THREE SECTIONS

LEFT IN SITU. THEREFORE DURING

DISMANTLING THE SECTIONS SHOULD BE

SUPPORTED TO PREVENT INJURY TO

OPERATIVES.

Dismantling of the boiler is a reversal of the erection

procedure as previously detailed. Care should be

taken during dismantling due to the weight of the

sections and should be carried out by two operators

at a time.

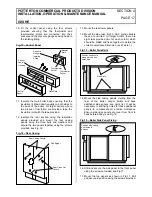

Fitting the Casing

To allow fitting of the electrical and fuel services it will

be necessary to fit casing panels as detailed in the

paragraphs 1 – 12 below, the flue spigot as

paragraph 19 and the burner as detailed under

relevant section. However, the remaining casing and

insulation can, if required, be fitted after construction

has ceased in the boiler house to minimise damage

to the casing.

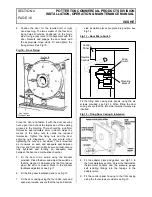

Fig.7 – Boiler Insulation

1. Fit the insulation strip to the front section as

shown in Fig.7 and secure in position using the

adhesive tape provided.

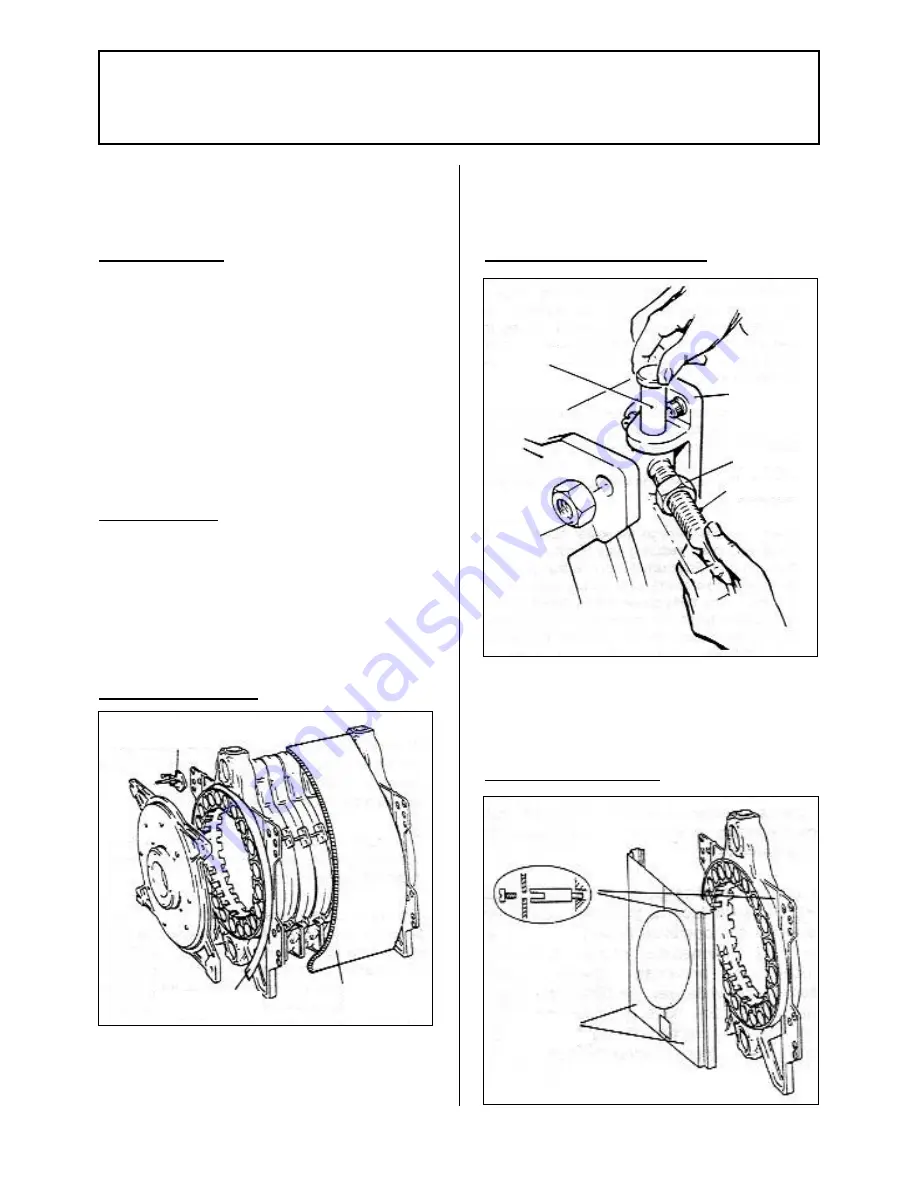

2. Fit firing door support brackets to the front face of

the boiler, together with four studs and securing

pins. Fit locknuts to the studs on the door hinge

side, see Fig.8

Fig.8. – Fitting Locknuts to Studs

3. Fit the eight hexagonal spacers to the front

section and fit the front boiler casing. This is a

two piece construction using eight machine

screws provided, see Fig.9.

Fig.9. – Front Panel Fixing

Front Door Support

Bracket

Front Insulation Strip

Boiler Body

Insulation

Fixing

Nut

Securing

Pin

Firing Door

Support

Bracket

Lock Nut

Hinge Stud

Fixing Spacer

Two Piece

Front Casing

Summary of Contents for Isis HE

Page 1: ...MAY 2004 ...