POTTERTON COMMERCIAL PRODUCTS DIVISION

SECTION 5

INSTALLATION, OPERATION & MAINTENANCE MANUAL

PAGE 21

ISIS HE

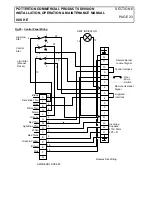

Boiler Controls

The operation of boiler controls including control

thermostat, high/low thermostat and overheat

thermostat should be checked on an annual basis

and the burner recommissioned as detailed below.

Safety Interlocks

The operation of safety interlocks such as flow

proving on mechanical flue/ventilation systems

should be checked to ensure that operation of the

boiler is prevented on a fault.

COMMISSIONING

IMPORTANT: The boiler must be commissioned

following completion of installation. Operation of

an uncommissioned appliance may cause injury

to personnel and damage to the boiler/burner unit

and could invalidate the manufacturers

warranties.

Commissioning should only be carried out by

personnel approved and competent to do so. This

facility is available from Potterton Commercial

Service Offices at the addresses as listed on the

back page of this manual.

Commissioning of the burner unit should be carried

out in accordance with the burner manufacturers

handbook provided with combustion adjustments in

accordance with the Potterton burner data sheet also

provided.

Before commencing to commission the burner check

the following.

1. Electrical supply is of correct voltage and polarity

and earthing is available.

2. Fuel supply is tested for leakage and purged of

air. Ensure the burner is suitable for the

connected fuel supply and pressure.

3. Boiler and system are fully flooded with water

and the operating pressure is within the

appliance range.

4. Pumps are operational and any flow proving

interlocks are functional. The operation of the

pump should be checked, particularly on sealed

systems, to ensure that operation does not cause

a reduction in pressure within the system below

the minimum operating pressure. See section 3

for further details on water circulation systems.

5. Ventilation is adequate and, in the case of

mechanical ventilation systems, operation of the

boiler is inhibited unless the ventilation fan is

proved.

6. On mechanically assisted flue systems the

operation of the boiler plant should be inhibited

unless the mechanical flue system is operational

and flow proved.

7. The safety valve should be checked to ensure

that it is of the correct size and pressure. See

Section 3 for further details.

8. The cold feed and open vent sizes should be

checked. See Section 3 for further details.

9. Ensure the burner fitted to the boiler is of the

correct specification and size for the boiler and

suitable for the fuel supply available.

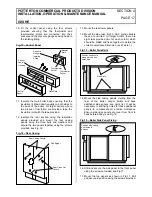

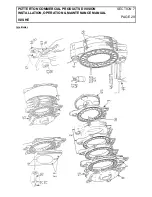

10. The burner blast tube has been sealed to the

door refractory and the boiler door seal is correct.

See Section 4 for further details.

11. The sight glass cooling tube is connected

between the boiler sight glass and burner body.

IMPORTANT: Operation of the burner without the

cooling tube connected can lead to boiler damage

and a hazardous condition occurring.

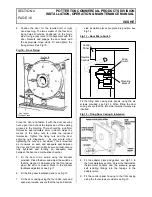

12. The boiler door micro switch prevents operation

of the burner when door seal is broken.

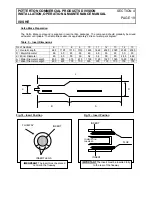

13. The boiler inserts have been correctly fitted, see

Section 4.

Following completion of the above checks the burner

should be commissioned in accordance with the

burner manufacturers handbook provided with the

burner. The combustion figures, etc. should be

completed on the commissioning form provided at

the back of this manual and returned to Potterton

Commercial at the address on the back page.

IMPORTANT: The boiler/burner units are supplied

in accordance with Potterton Commercial Quality

Assurance plan registered to meet the

requirements of BS 5750 Part 2. A condition of

the supply of the appliance for compliance with

this Quality Assurance plan is the return of the

appliance commissioning report.

Following/during commissioning of the burner unit the

following additional checks should be carried out.

14. Operation of the control, high/low and high limit

thermostats should be checked for correct

operation.

Summary of Contents for Isis HE

Page 1: ...MAY 2004 ...