6.0

OPERATIONAL SAFETY CHECKS

6.1

Check control stat operation

6.2

Check limit stat operation

6.3

Check high/low stat operation

6.4*

Check for gas leaks

6.5*

Check for gas leakage past valve assembly

6.5¶

Check for oil leaks

6.6

Check boiler locks out on loss of flame signal

6.7

Check boiler locks out on air pressure switch

operation

6.8

Check boiler locks out on all other safety

functions

6.9*

Check gas booster interlocks operational

6.10

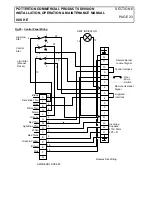

Record INLET and OUTLET pressure switch settings:-

INLET ………………….. OUTLET …………………

7.0

BOILER/SYSTEM CHECK LIST

7.1

Control stat left at

°C

7.2

Limit stat left at

°C

7.3

High/low stat left at

°C

7.4

Maximum flow temperature recorded

°C

7.5

Maximum return temperature recorded

°C

7.6

Boiler water pressure

7.7

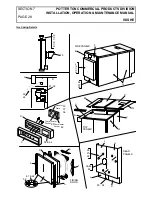

Are pipework connections as per manual?

Is safety valve fitted?

7.8

If so, SIZE _________________________

PRESSURE RATING ___________________

7.9

Are water isolating valves fitted?

7.10

Are water flow switches fitted?

7.11

Are return water shut off or diverter valves fitted?

7.12

Is shunt pump fitted?

7.13

Is pump overrun fitted?

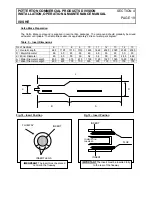

Flue type and diameter of connection to boiler:-

TYPE ………………………DIAMETER (mm) …………

Where appropriate and for multi boiler installations

sketch details of flue system showing length of runs

and diameters.

Conventional

Fan Assisted

Flue Dilution

7.14

Approximate overall height ………………………….. m

Is the fan interlocked with the boiler?

YES / NO

7.15

Are flue dampers fitted?

YES / NO

If so, interlocked?

YES / NO

7.16

Fan assisted ventilation?

YES / NO

7.17

Any evidence of condensate formation?

YES / NO

7.18

Any evidence of water leakage?

YES / NO

7.19

Any evidence of flue gas leakage?

YES / NO

7.20

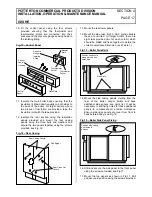

Has boiler been built and cased correctly? YES / NO

7.21*

Is gas service cock installed?

YES / NO

If so, accessible?

YES / NO

7.22¶

Is oil filter fitted?

YES / NO

7.23¶

Is fire valve fitted?

YES / NO

Oil supply:

Single Pipe

Two Pipe

7.24¶

Ring Main

8.0

COMMENTS ON ACCESSIBILITY FOR MAINTENANCE

9.0

NOTES & COMMENTS BY COMMISSIONING

ENGINEER

FINDINGS

YES

NO

Is the installation safe for use?

If the answer is NO, has a warning label been

raised?

Is any remedial work required?

Have warning labels been fitted?

Has RIDDOR form been raised?

Customer Signature:

Print Name:

Date:

ENGINEER DETAILS

NAME

COMPANY

SIGNATURE

DATE

Baxi Heating Ltd.

Reg.Office: Pentagon House, Sir Frank Whittle Road,

Derby DE21 4XA – Registered in England 3879156

Document ID Ref: PCF/029/3

Summary of Contents for Isis HE

Page 1: ...MAY 2004 ...