52

NXR5i

25/09/2012 - 300029104-001-02

62 package MR338 or MR339

`

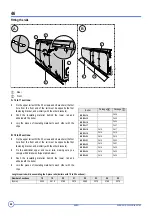

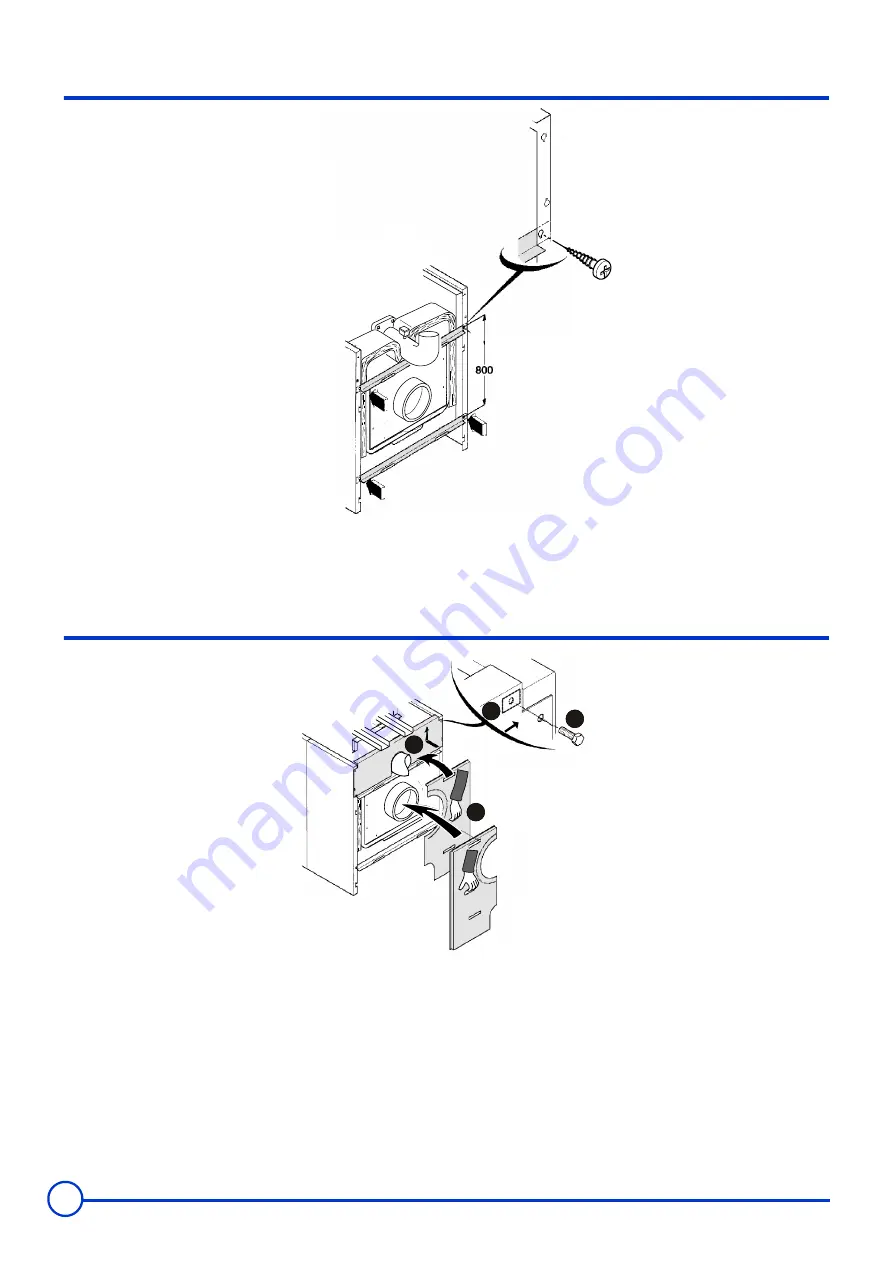

Put in place the 2 rear crosspieces (package MR338 or MR339)behind the bend of the rear side panels and fasten each crosspiece to

the side panels using 2 screws (Ø 3.94 x 12.7).

63 package MR338 or MR339

`

Put the 2 clip-on nuts in place on the side panels

.

`

Fit the upper rear panel (package MR338 or MR339) onto the studs and push it up

.

`

Fasten with 2 screws (H8 x 16) and serrated washers

.

`

Fit the 2 lower rear panels (package MR338 or MR339) onto the rear crosspieces

.

M000126

1

3

4

2

M0

7

0012

Summary of Contents for NXR5i

Page 1: ...NXR5i Fuel oil gas boilers Assembly Instructions C003966 A 300029104 001 02 EN ...

Page 46: ...46 NXR5i 25 09 2012 300029104 001 02 51 L000068 B C003955 B 3 4 2 4 4 1 ...

Page 47: ...47 25 09 2012 300029104 001 02 NXR5i 52 53 C003956 B 1 3 4 2 C003957 ...

Page 57: ...57 25 09 2012 300029104 001 02 NXR5i ...

Page 58: ...58 NXR5i 25 09 2012 300029104 001 02 ...