SECTION 4

POTTERTON COMMERCIAL PRODUCTS DIVISION

INSTALLATION , OPERATION AND MAINTENANCE MANUAL

PAGE 14

PARAMOUNT

Gas/Air Ratio Control:

With the gas/air ratio control

for the PARAMOUNT, the gas supply is adapted to

the air supply, which is factory set. Adjustment

should be accomplished at maximum and minimum

nominal heat input, called full load and minimum load

below.

Changing over from LPG to Natural Gas or Vice

Versa:

The type of gas for the PARAMOUNT boiler

should be changed only by an authorised gas

installer. To convert, replace the gas injector (Table

5) and adjust the CO

2

content by adjusting the

injector pressure on the gas valve. The CO

2

content

should be between the following values at full load as

well as at minimum load:

CO2 content (natural gas): 8.3% - 8.8%

CO2 content (LPG) 9.5% - 10.0%

Put the sticker with the gas (provided with the kit) on

the gas pipe.

Adjusting and Checking the Values:

Operate the

PARAMOUNT in the

controller stop mode

to adjust

and CO2 values.

Controller Stop Mode (manual adjustment of

burner capacity):

In the controller stop mode, the

burner can be set to all loads within the modulation

range. Check the adjustment of the CO

2

values at full

load and minimum load.

Activate the controller

stop mode on the boiler module

(1)

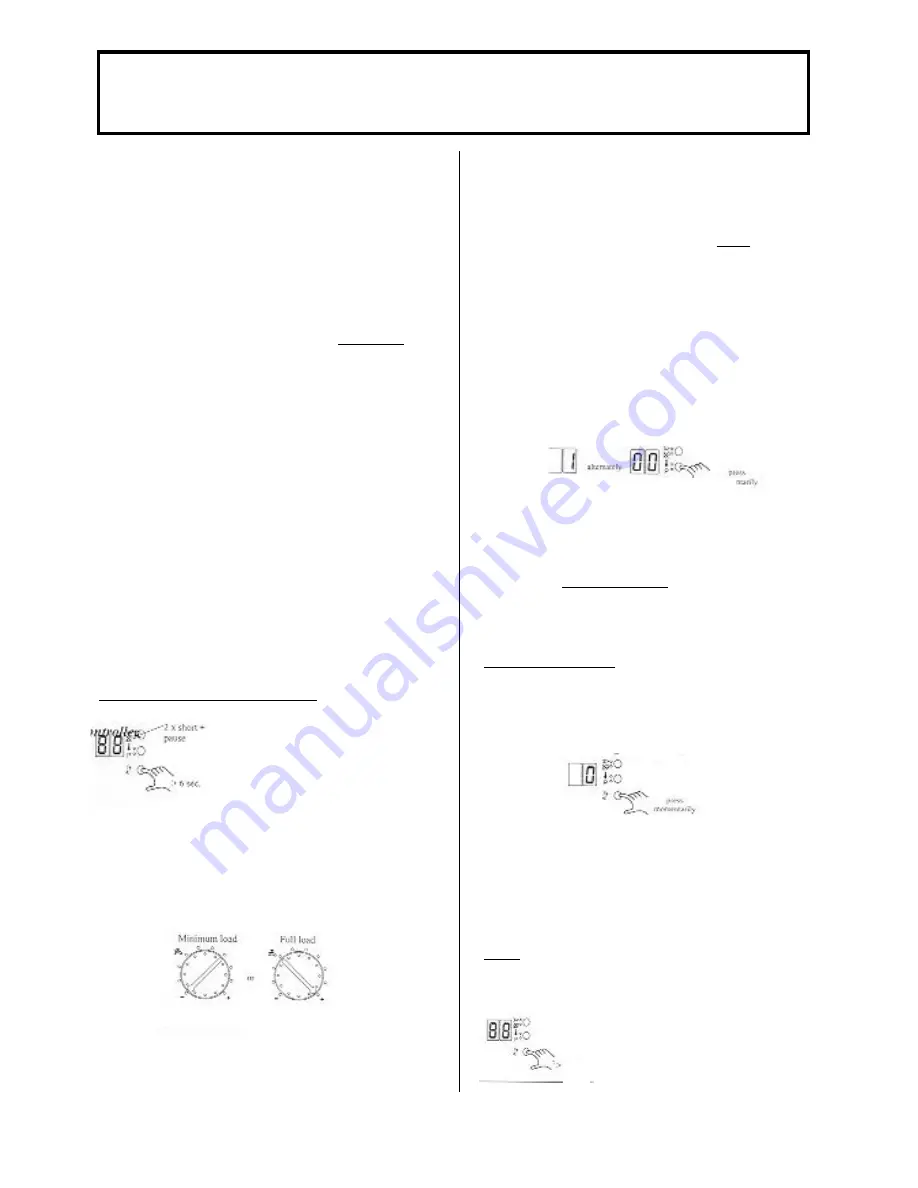

Activating Controller Stop Mode:

Hold the “Chimney Sweep” button

(12) down for

more that 6 sec

.

until the display “Fault” (8)

flashes in red

at intervals (2 x

short and pause). The current,

relative burner load then appears

on the display (0=min; 100 =

max.) whereby the number 100 is

output in the form of a 1 and 00 in

sequence.

Setting Controller Stop Mode 1

st

possibility, on

heating circuit module HKM:

After activating the controller stop mode on the boiler

module, adjust the burner capacity on the HKM with

the hot water control.

Left Stop: Minimum load (-)

Right Stop: Full Load (+)

New settings are taken over immediately by the

BMU.

Important:

It is always necessary to adjust both

settings (full load and minimum load)! After adjusting

the minimum load, check the full load again.

On Room Control Module RRG: Not Possible:

It is

not possible to activate and adjust the controller stop

mode on the RRG! However, the display can be

called up at the RRG info level.

Completing CO

2

Adjustment:

To complete the CO2

adjustment, deactivate the controller stop mode by

pressing the “Chimney Sweep” button (12) > 1 sec.

and then releasing.

2

nd

Possibility, on boiler module:

Adjustment of the full load and minimum load on the

boiler module can be accomplished with the following

steps:

100 does not appear on display (13):

To set the max. boiler load momentarily press the

“Display Mode” button (10). The value “100” appears

on display (13) i.e. the burner (fan) is now running at

the setting for the max burner load.

GAS VALVE Setting

Full Load Setting On Gas Valve Then set the gas

valve to full load adjustment screw for full load,

(Fig.9) (see guide value For CO

2

).

Minimum Load Setting:

To adjust the minimum boiler load momentarily press

the “Chimney Sweep” button (12). The value “0”

appears on the display (13) i.e. the burner (fan) is

now running at the setting for min. burner load. Then,

the minimum load can be set on the gas valve

9adjustment screw for minimum load) (see guide

value for CO

2

). Then check the full load, if the gas

valve has been readjusted, check the minimum load

again!

CO

2

Adjustment

To complete the CO2 adjustment,

deactivate the controller stop mode by

pressing the “Chimney Sweep” button

(12) >

1 sec

and then releasing.

Full load setting