Publication No. 5106226

20

MAX0022C

-

+

PROG

SEL

PROG

SEL

-

C.H. ADVANCE

H.W. TEMP

RESET

BURNER

LOCK OUT

MAINS ON

POWER

+

RWC

This Appliance

Must Be Ear

thed

N

L

N

F HW HW CH CH

T

T

R

L

L

R

R

L

R

2

L

2

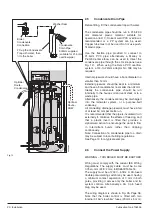

Fill up the Condensate

Trap with water, then

fit to the boiler

Condensate

Drain Pipe

500mm supplied

(suitable for 21.5mm

overflow pipe)

Washer Seal

Boiler

Condensate

Connection

Optional

Route -

DHW

Optional

Route -

Condensate

Fig. 12

Installation

2.5

Condensate Drain Pipe

Before fitting, fill the condensate trap with water.

The condensate pipe should be run in 21.5/22.0

mm diameter plastic material suitable for

operation at 60° C. Solvent weld PVC overflow is

recommended or a PP system can be used.

Copper tube must not be used. Do not use push-

fit plastic pipe.

Use the flexible pipe provided to connect to

21.5mm PVC pipe; alternatively a Marley or

Plumb Center elbow can be used to direct the

condensate pipe through the LH side panel (see

Fig. 12). When using the Osma PVC overflow

system, a 3/4 -to-22mm adaptor No. 158 may be

required.

Internal pipework should have a bore diameter no

smaller than 14 mm.

External pipework should be kept to a minimum,

and have a bore diameter no smaller than 32 mm.

Ideally the condensate pipe should be run

internally to the house soil and vent stack or to a

waste pipe.

Alternatively, the condensate may be discharged

into the rainwater system, or a purpose-built

soakaway.

All connecting drainage pipework must have a fall

of at least 50 mm per metre run.

It is recommended that the pipe is insulated if run

externally to minimise the effects of freezing, and

that a plastic insert is fitted that provides a

siphon/weir action to encourage the water to flow

in intermittent bursts rather than dripping

continuously.

Note: Connection of a condensate pipe to a drain

may be subject to local building regulations.

See Page 19 for a typical example.

2.6

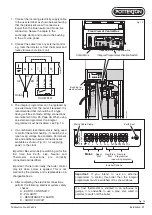

Connect the Power Supply

WARNING – THIS BOILER MUST BE EARTHED

Wiring must comply with the current IEE Wiring

Regulations. The supply cable must be 3-core

0.75sq. mm (24/0.2 mm) to BS6500 Table 16.

The supply must be of 230V – 50Hz. A 3A-fused

double pole-isolating switch may be used, having

a minimum contact separation of 3 mm in both

poles, providing it serves only the boiler and its

system controls. Alternatively a 3A 3 pin fused

plug may be used.

The wiring diagram is shown in Fig. 25, Page 36.

Note that the boiler control is fitted with two

internal 3.15A “slow blow” fuses (20 mm x 5 mm).