Publication No. 5106226

29

Powermax

-

+

SEL

SEL

-

+

MAIN

S ON

POW

ER

CH

HW

PRO

G

PROG

C.H. A

DVAN

CE

H.W. TE

MP

RES

ET

BUR

NER

LOC

K OU

T

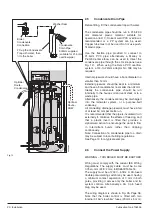

Isolating

Valve

Closed

Open

Isolating

Valve

Pump

Isolating

Valve

Disconnect

Pump

Connector

Remove Expansion

Vessel Support Bracket

Bulkhead

Push Fit Elbow

Metal Washers

2 Fibre

Washers

Lift Out

Pump

Pump

Bottom

Pipe

Pump Top

Pipe

Pull

forward

Expansion

Vessel

Disconnect

Flexible Pipe

Washer

Washer

Pressure Relief

Valve

Loosen when removing pump

complete

MAX0015C

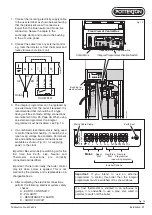

Disconnect

Pump

Connector

Rotate Pump

to Access

the Pump

Motor

Pump

Motor

Remove 4

Securing Screws

Open

Auto

Air

Vent

Cap

Open Pressure

Relief Valve

Expansion Vessel

Gas Cock

Isolating Valve

4.3

Expansion Vessel/Pump

Re-assemble all parts in reverse order.

1. Perform 4.1 General Access. Also remove

the moulded facsia panel (2 screws).

2. Isolate three valves as shown and open

the cap on the auto air vent.

3. Release pressure by opening the

pressure relief valve.

4. Remove expansion vessel

Remove securing screws and support

bracket. Disconnect flexible pipe at the

vessel. Pull vessel forwards and out of the

boiler.

5a.

Pump Motor

Loosen the top pipe union nut at the

pump.

Disconnect electrical connector from the

pump motor. The pump can now be

rotated so the motor retaining screws can

be removed

5b.

Pump Complete

Disconnect the top pipe union nut at the

pump. Disconnect electrical connector

from the pump motor. Loosen 22 mm

compression nut on cross fitting, lift the

pump up and it will disconnect (complete

with pipe) from the push fit elbow.

Important:

Ensure that the metal washer

is located between the push fit elbow and

the bulkhead and also above the rubber

washers on top of the bulkhead. This will

ensure that the pump can be easily

removed in the future.

Fig. 18

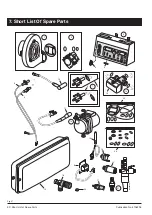

Replacement of Parts