Publication No. 5106227

2

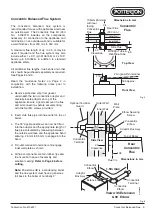

Flueing

This is a “room sealed” condensing appliance.

Flue

systems are supplied in kits, or components can be

ordered individually from Potterton. Only Powermax flue

components (which are designed for condensing

operation) can be used.

Flue Systems

All appliances are supplied to accept the Powermax 60

mm dia. twin flue system, however several flue system

options are available.

Each system is room sealed and offers a choice of flue

type and termination method, see Fig. 2.

• Concentric balanced flue with horizontal terminal

• Twin flue with vertical terminal *

• Twin flue with pitched roof terminal *

• Twin flue with horizontal mini terminal

Flue kits are available for each of the above options and

each kit contains all of the components needed for

connection to the appliance and terminal.

Flue

extension lengths and bends should be purchased

separately, as required.

* These terminals must be ordered/specified separately.

Flue Protection

When using an extended flue system it is essential to fit

protective ducting (such as that supplied in the extended

flue kits) in order to prevent direct contact with the hot

flue pipe, See Page 7.

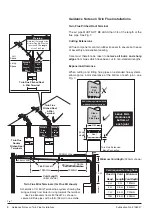

General Requirements for Horizontal Flue

Terminations

Detailed recommendations for flueing are given in

BS5440: Part 1. The following notes give general

guidance. The horizontal balanced flue terminal must be

installed so that it is exposed to external air, preferably

on a clear expanse of wall. Acceptable positions are

indicated in Fig. 3. Avoid positions where the terminal is

adjacent to projections; particularly immediately under a

balcony, inside a re-entrant position, or immediately

adjacent to a drain pipe. If the appliance is fitted under

a ventilator or opening window, the terminal must be at

least 300 mm from any part of the window or ventilator

and in accordance with BS5440: Part 1.

The flue pipe must not be closer than 25 mm to

combustible material. Additional clearance must be

provided when passing the flue through timber walls.

Advice on gas installations in timber framed buildings is

contained in IGE technical publication IGE/UP/7

available from the Institution of Gas Engineers, 21

Portland Place, London W1N 3AF.

Guidance notes for Flue Installation

Read these Installation Instructions before installing

the boiler

. Before starting an installation, check that the

correct flue kit has been supplied with the boiler.

Detailed recommendations for flue installations are given

in BS 5440:1: 2000. The following notes are for general

guidance only.

a) The flue system must be constructed using only

Powermax approved components.

b) It is important that the position of the terminal allows

free passage of air across it at all times.

c) It is ESSENTIAL TO ENSURE that products of

combustion discharging from the terminal cannot re-

enter the building, or any other adjacent building,

through ventilators, windows, doors, other sources of

natural air infiltration, or forced ventilation / air

conditioning.

d) The minimum acceptable dimensions from the flue

terminal to obstructions and ventilation openings are

specified in Figs. 3 & 4 on Page 4 of these instructions.

e) If the flue terminal discharges into a pathway or

passageway check that combustion products will not

cause nuisance and that the terminal will not obstruct

the passageway.

f) Where terminals are fitted within 850 mm of a plastic

or painted gutter, or 450 mm of painted eaves, an

aluminium shield at least 750 mm long must be fitted

to the underside of the plastic or painted surface.

g) Where installation will be in an unusual location,

special procedures may be necessary. BS 6798 gives

detailed guidance on this aspect.

h) As the Powermax is a condensing appliance the flue

duct must have a generous fall back to the boiler of

nominally 2°.

j) The efficient condensing operation of the Powermax

HE will naturally give rise to condensation in the flue

gases and

pluming will occur in all but the most

favourable atmospheric conditions

. Some

condensate may also be discharged from the terminal.

The terminal must, therefore, be

sited to avoid

nuisance from either phenomenon

.

k) Where the lowest part of the terminal is less than 2 m

above the level of any ground, balcony, flat roof or

place to which people have access, the terminal must

be protected by a guard of durable material. A Terminal

Guard, Part No. P210 is available from Potterton. The

guard requires a flat wall surface of approximately 330

mm diameter, concentric with the terminal assembly.

Flueing