Publication No. 5106227

11

MAX0042A

Flat Roof Flashing

Felt Roof

Ø180

Top Felt Layer

Bitumen

100mm Felt Collar

Bottom Felt

Roof Construction

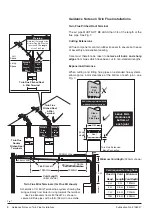

Flat Roof Flashing

Asphalt Roof

Ø180

Apply sealant to

the edge such as

butyl or mastic

before fitting terminal

Asphalt

Roof Construction

Note:

Damage to the seals could result in

condensate/flue products leakage from the flue

system.

Note:

Due to the high efficiency and reduced

flue gas temperature of the Powermax HE, little

or no buoyancy is generated in a vertical length

of the 60 mm Ø flue pipe and installations

should therefore be designed with this in mind.

Fixing Flat Roof Flashing

Installation of the flat roof flashing unit must be

carried out by a competent flat roofing contractor.

The following notes are for the contractor’s

guidance. Avoid locating the flat roof flashing in a

position where standing water is likely to

accumulate.

For built up felt roofs, see Fig. 13.

1. Cut 180 mm diameter service opening through

roof construction and first layer of felt.

2. Bed flange of unit on to felt with bitumen.

3. Dress top layer(s) of felt over flange of unit.

4. Star cut a hole in the top-most layer and finish

by detailing a 100 mm high felt collar around

upstand.

5. Apply a butyl or mastic sealant around the

spigot on the flashing unit and carefully lower

the terminal into position, ensuring that the

spigot seats securely inside the terminal rim.

6. From inside the building fit the 131 mm

diameter pipe support bracket around the

projecting flue pipe and screw flanges to

support timber or structure. Ensure flue

terminal is positively secured and vertical.

For Asphalt Roofs, see Fig. 14.

1. Cut 180 mm diameter service opening through

roof construction and sheathing felt and firmly

locate the flashing unit in position over it.

2. Dress asphalt over aluminium flange and up

neck offset of flashing unit ensuring it does not

move from location.

3. Apply a butyl or mastic sealant around the

spigot on the flashing unit and carefully lower

the terminal into position, ensuring that the

spigot seats securely inside the terminal rim.

4. From inside the building fit the 131 mm

diameter pipe stabilising bracket around the

projecting flue pipe and screw flanges to

supporting timber or structure. Ensure flue

terminal is vertical and positively secured.

Fig. 13

Fig. 14

Flashing Kits - Flat & Pitched Roof