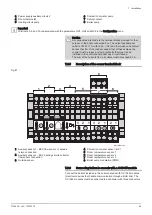

5. Fit the circulating pump on the heating return pipe (circulating pump

not provided).

7.3.2

Connecting the expansion vessel

1. Determine the volume of the expansion vessel according to the

volume of water in the heating circuit.

2. Connect the expansion vessel to the heating circuit return pipe.

Volume of the expansion vessel on the heating circuit

Terms and conditions of validity:

Safety valve calibrated to 0.6 MPa (6 bar).

Average water temperature: 70°C.

Heating circuit flow temperature: 80°C.

Heating circuit return temperature: 60°C.

Filling pressure in the system lower than or equal to the initial pressure

in the expansion vessel.

See

The expansion vessel complies with the BS EN 13831 standard.

The size of the expansion vessel complies with the BS 7074

standard, part 1.

Abide by the regulations on filling the heating circuits with water:

BS 7074

BS 6644

BS EN 12828

Caution

Only qualified professionals are authorised to carry out

maintenance work on the boiler and the heating system.

7.3.3

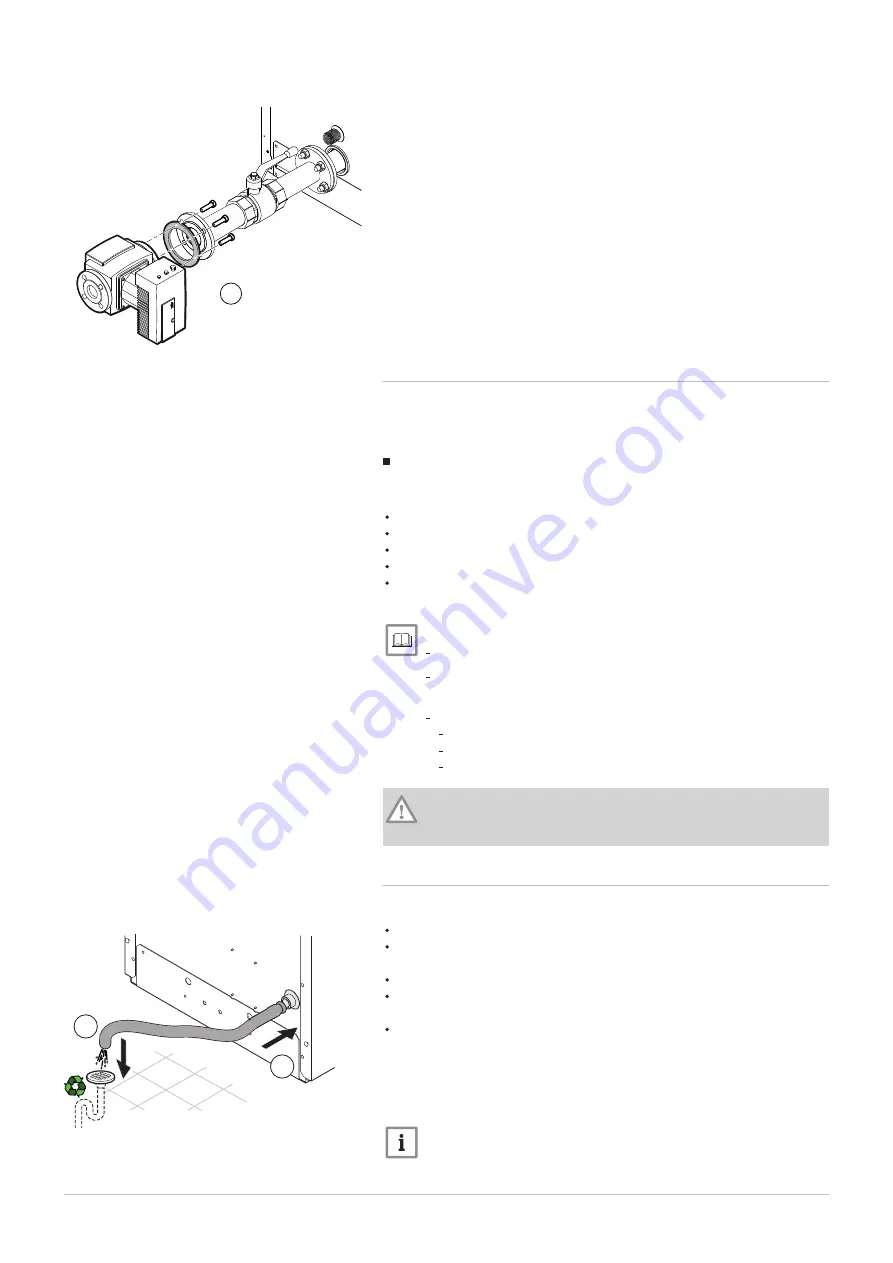

Connecting the condensate discharge pipe

The condensate discharge pipe is located inside the boiler.

Do not block the condensate discharge pipe.

Set the discharge pipe at a gradient of at least 30 mm per metre,

maximum horizontal length 5 metres.

Do not drain condensation water into a roof gutter.

Connect the condensate discharge pipe in accordance with prevailing

standards.

It is preferable to use the condensate neutralisers recommended by the

manufacturer of the boiler.

1. Connect a plastic hose to the condensate discharge outlet (DN18) or

a rigid pipe (DN32).

2. Insert the other end of the hose into a waste water discharge outlet.

Important

Treat the condensate in accordance with prevailing local

regulations.

Fig.71

MW-5000810-2

5

Fig.72

MW

-3

0

0

0

0

3

2

-0

3

1

2

7 Installation

60

7702639 - v03 - 10072018