Installation - Page 31

2.13

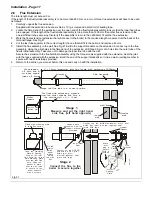

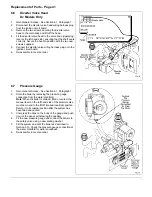

Connect the Water System

& Vent the Boiler

1.

Ensure that the plastic plugs are removed from the pipe

ends and attach the isolation valves. Check the valves

are open.

2.

Install the pressure relief valve discharge pipe (min.

15mm dia.) and connect to the pressure relief outlet

using a 15mm compression fitting. This will enable the

connection to be undone if the boiler has to be

removed.

Important:

The pipe run should be as short as

possible, run continuously downwards and discharge

outside the building and over a drain. It must not

discharge above an entrance, window, any type of

public access point, any point where it would be

hazardous to occupants or cause damage to external

electrical components or wiring.

3.

Screw the pressure gauge connection into the water

manifold, leave the facia hanging down.

4.

Fill the system, ensure that all valves are open.

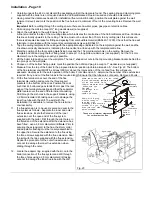

Dv Models Only:

The manual lever on the left hand

side of the diverter valve, must be moved from 'AUTO'

to 'MID' (manual override) when filling, venting or

draining the system.

Thoroughly flush the system through. A radiator type air

vent is positioned on the left hand side (at the front) of

the heat exchanger (on 80 models a second vent is

positioned at the rear).

5.

Refill and vent the system.

6.

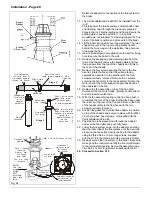

The pump bearings and shaft rely on system water to

provide lubrication. It is important therefore to ensure

that the bearings have been properly vented and

that

the

pump is not run dry

otherwise damage may occur

to the bearings. Unscrew the pump manual restart

knob, and withdraw it to engage in the motor shaft.

Rotate the knob and check that the motor shaft rotates

freely. Apply a sideways pressure to the knob until a

small amount of water becomes visible. The pump is

now vented. After use, the manual restart knob should

be screwed back into its original position, finger tight.

Take care not to allow any water to drip onto the control

box or other electrics.

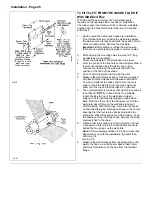

7.

Pressurise the system to 1.5 bar and check for leaks,

rectifying where necessary. Reset the system pressure

to 0.8 bar and set the red adjustable pointer on the

pressure gauge to 0.8 bar.

Fig. 38

Summary of Contents for Ultra 2

Page 6: ...Installation Requirements Page 6 Fig 1 ...

Page 7: ...Installation Requirements Page 7 Fig 2 ...

Page 9: ...Installation Requirements Page 9 ...

Page 37: ...Routine Maintenance Page 37 ...

Page 51: ...7 Wiring Diagrams Page 51 ...

Page 52: ...Wiring Diagrams Page 52 Ultra 2Dv ...

Page 53: ...Wiring Diagrams Page 53 Ultra 2 ...

Page 54: ...54 Fault Finding Part No 405 0522 8 Fault Finding Guide Page 54 ...

Page 55: ...Part No 405 0522 Fault Finding 55 Fault Finding Guide Page 55 ...

Page 56: ...56 Fault Finding Part No 405 0522 Fault Finding Guide Page 56 ...

Page 57: ...Part No 405 0522 Fault Finding 57 Fault Finding Guide Page 57 ...