- 13 -

1300 GB_TRANSPORT_3784

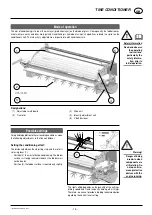

TRANSPORT- AND WORKING POSITION

GB

Safety Precaution!

see supplement-

A1 points 7.), 8c.

- 8h.)

Changing from

working positi-

on to transport

position is only to

be carried out on

even, firm ground.

Never run the mo-

wer in transport

position.

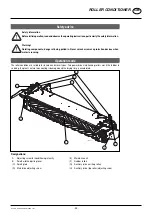

Changing from transport position to

working position

Procedure:

Be alert!

Ensure that no one is standing in the

mower’s swivel range!

1) Pull control line

2) At the same time swivel the mower into field transport

position until the swivel cylinder is completely extended

using the dual-action control unit

Note:

If the dual-action control unit is activated

without having pulled the control line, then

the horizontal position of the hitch changes!

3) Set the single-action control unit to floating position and

thus lower the mower into working position

4) Set the dual-action control unit to floating position so

that the collision safety device works to the optimum.