- 32 -

1100_GB-ISOBUS-Terminal_3843

GB

ISOBUS - TERMINAL

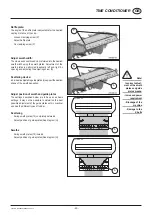

Diagnostic Function

Monitoring of the job computer for

operating voltage

sensor supply voltage

short-circuit to ground or 12 V

cable break

overload

Switching outputs

(example: Y1 = raise directional control valve)

On fault identi

fi

cation

- the alarm screen is faded in and an alarm sound is audible.

- the corresponding symbol and fault are displayed.

An error must be acknowledged using the “ESC” key.

The diagnostic function for every single channel can be switched off

until the next system start using the

“T9”

key.

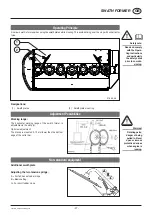

Note!

Any desired function may be established manually

using the emergency actuator in the event of a

malfunction (see Section “Electrohydraulics”).

Sensor inputs

(example: sensor voltage supply < 10 V)

Note!

The alarms for the voltage supply cannot be switched

off.

T

9

Diag

Diag

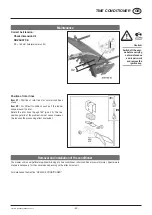

Calibration

Starting from the SET menu (

F6

) the “Test” button

must be

pressed for 10 seconds to enter the diagnostic menu.

a

b

c

d

e

a

Pivoting aid

This configuration must be deactivated in the case of Novacat

X8 and X8 Collector!

b

Individual cross conveyor belt pivoting

c

Diagnostic function of the inputs and outputs

d

Hydraulic pressure relief

e

Speed control of the cross conveyor belts

(tick = active/cross = inactive)

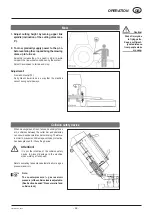

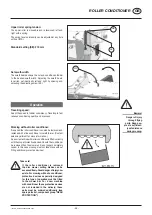

Time out monitoring

When, after 6 seconds and after pressing the “Raise front mower or

all mowers” button, the front mower sensor is not reached.

Note:

When

this message is displayed, the front mower S7

sensor is not active.

Immediate

action:

- Check whether the front mower has been activated

in the SET menu!

- Check sensor lines!

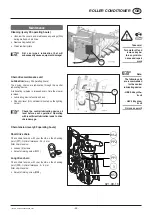

Diag