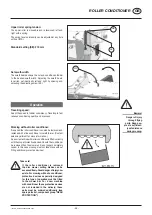

Altering the roller position:

(when required)

After the drive chains have been tensioned several times

the roller position changes.

Alter roller position:

Loosen the screws (WS) and rotate the roller. Set the

position of the lower roller so that the profile of both rollers

is optimally interlock and not touch each other.

Optimal roller position prevents premature

wear and tear of the rubber rollers.

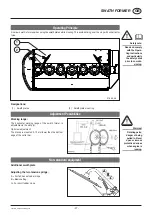

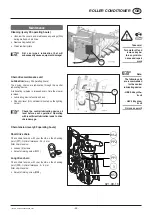

Drive belts: (when required)

Check belt tension:

• Standard setting (SE): XX mm

Alter belt tension:

• Adjust screw (WS)

Replace belts:

When the drive belts show signs of damage or wear,

they must be replaced.

(Attention: Always replace the

complete belt set!)

• Loosen belt tension. To assist, the belt tightener can

be deactivated using the cutter quick-change spanner

(1)

• Replace belts

• Reset belt tension

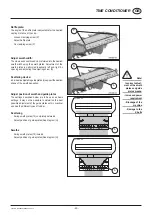

Lubrication:

(every 20 operating hours)

• SP 1

(every 100 operating hours)

• SP 2 (Unscrew the top cover to lubricate!)

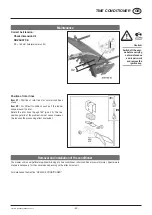

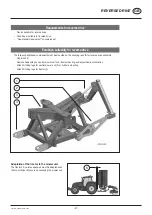

Transmission oil:

(every 100 operating hours)

The gearbox is on the outside of the cutter bar.

• Open the drain screw (AS) and drain off oil

• Pour in transmission oil (700 ml) at filling screw (BS)

Fully synthetic lubricating oil for high-temperature

lubrication, ISO-VG-Class 220)

WS

021-09-11

RS

SE

BS

AS

SP1

SP1

SP2

- 46 -

1000-GB_WALZENAUFBEREITER_3843

ROLLER CONDITIONER

GB