0200-GB ELEK-HYD_537

- 19 -

GB

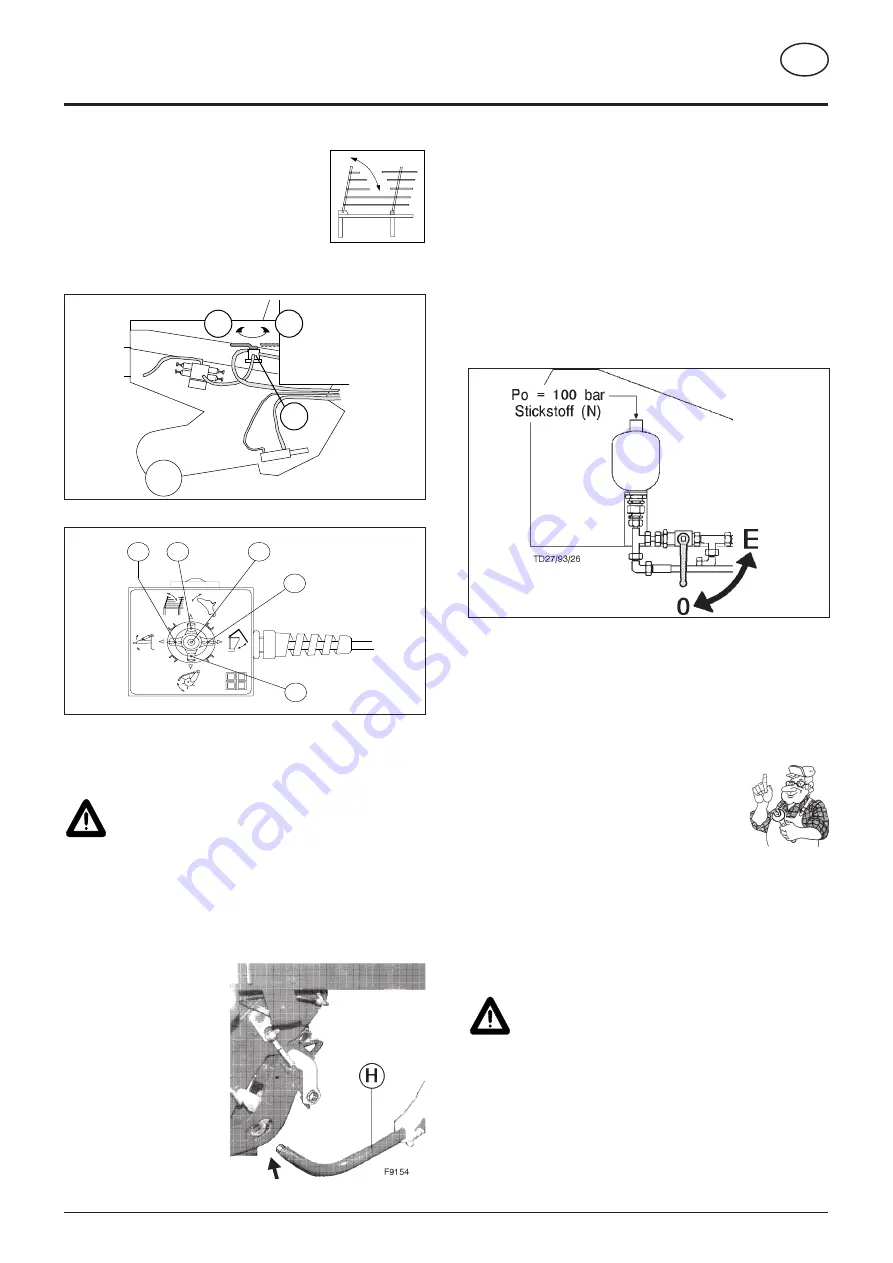

ELECTROHYDRAULIC OPERATION

SW

DA

TD 18/93/13

W

TD 18/93/9

A

B

C

D

E

Dry forage extension

- Lever (W) in position "DA".

- Lever on control panel in position "B".

- Engage servo-control (ST) on tractor.

Folding extension up or back gradually.

Swivelling cutter unit

Caution!

Do not reach into swivel range of cutter bar

when swivelling in / out.

- Lever (W) in position "SW".

- Lever on control panel in position "B".

- Engage servo-control (ST) on tractor.

Both cutter bars swivel in resp. out.

• When only one cutter bar

is needed for mowing, the

lower cutter bar can be

swivelled out using the

accoompanying lever (H).

Obstructions when swivelling

- Remove foreign body from swivel range.

• If the cutter bars do not swivel in properly, then a pressure

loss in the cutter unit hydraulic could be the cause.

Remedy by hydraulically filling the reservoir

- Move lever to position "E" on 3-way valve.

- Actuate servo-valve. The cutter bar is swivelled out

hydraulically.

- Leave servo-valve (ST) in the press position for a few

seconds while moving the lever on the 3-way valve to

position "0".

• If obstruction cannot be removed then check gas fill pressure

(100 bar nitrogen) in hydroreservoir.

Alteration of gas container pressure

• This work may only be carried out by customer service or a

specialist.

• In order to reduce or increase the pressure in

the gas container a special filling and checking

device is necessary.

Note

• According to manufacturer's information all

gas containers have a slight pressure drop

after a certain amount of time.

• The gas loss (nitrogen) amounts to 2-3 % per year.

• After 4-5 years it is recommended that container pressure be

checked and if necessary corrected.

Maintenance

Beware!

No welding, soldering or mechanical works of

any kind may be carried out on the container.

• Hydraulic oil change according to tractor manual.

• Before welding on trailer disconnect all plugs from tractor

and disconnect trailer.