0000-GB GELENKWELLE (341)

DRIVESHAFT

GB

Supplement - B

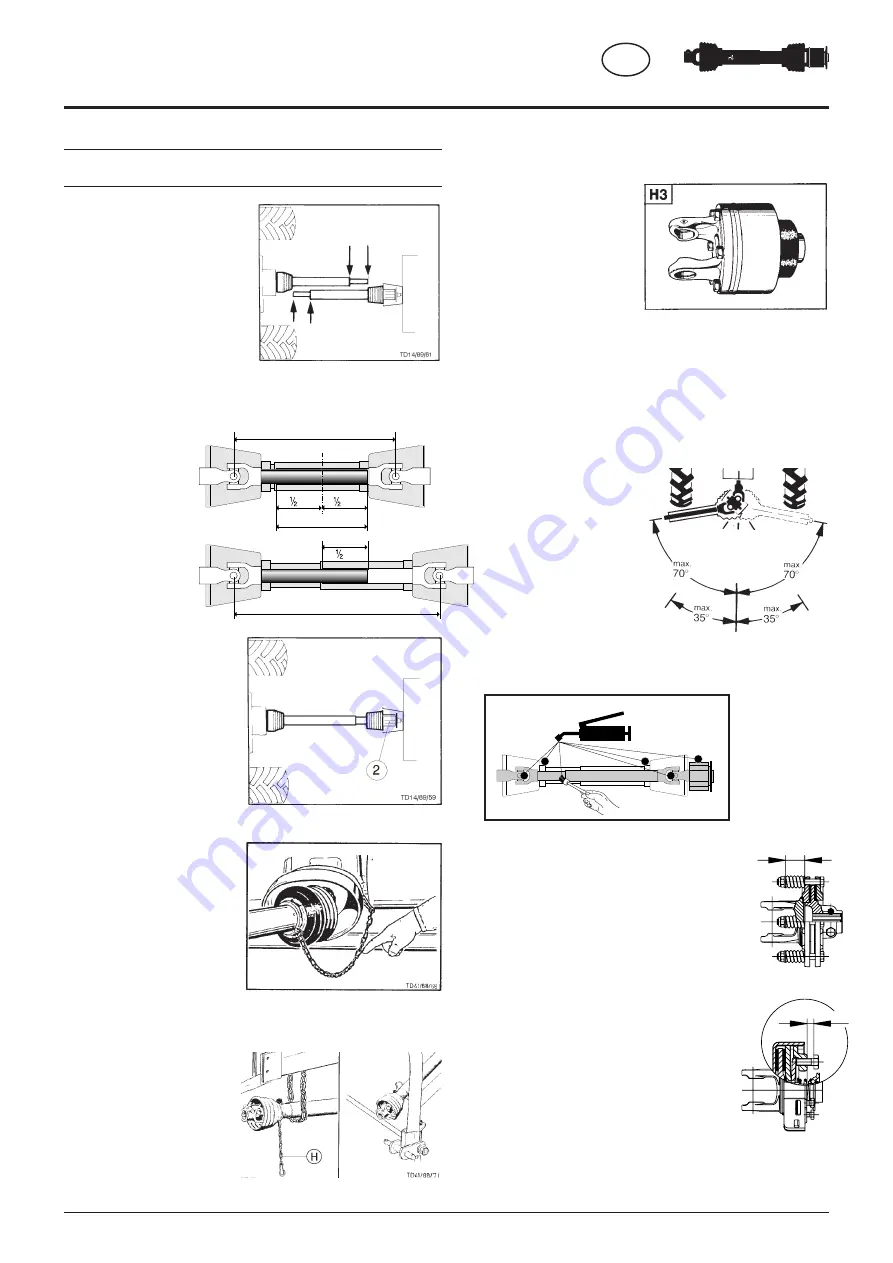

1) How a cam type cut out safety clutch

works:

This overload clutch switches

the torque transmitted to zero

if overloaded. To revert to

normal operation, stop the

p.t.o. drive briefly.

The clutch reengages at a

speed below 200 rpm.

IMPORTANT !

The overload clutch on the driveshaft is not a “Full up” indicator. It

is purely a torque limiter designed to protect the implement against

damage.

Driving the right way will avoid triggering the clutch too often, and

thus causing unnecessary wear on it and the implement.

2) Wide-angle joint :

Maximum angle of deflection when working/stationary : 70°

3) Standard joint :

Maximum angle of deflection

when stationary: 90°

Maximum angle of deflection

when working: 35°

Maintenance

Replace worn-out

covers/guards at once.

-

Lubricate with a brand-

name grease before starting work and every 8 hours worked.

-

Before any extended period of non-use, clean and lubricate

driveshaft.

For winter

working, grease

the tube guards,

to avoid them

freezing together.

• Important for driveshafts with friction

clutch

Prior to initial operation and after long periods out

of use, check friction clutch for proprer function.

a.) Measure dimension „L“ at compression spring

of K90, K90/4 and K94/1 or at set screw of

K92Eand K92/4E.

b.) Loosen screws to release the pressure on the

friction disk.

c.) Tighten set screws to dimension „L“.

Clutch is ready for use.

DRIVESHAFT

Important!

Only use the indicated or

accompanying drive shaft, otherwise

the right to claim under guarantee for

any possible damage does not exist.

Matching driveshaft to tractor

To determine the actual length

required, hold the two halves of the

driveshaft side by side.

Procedure for cutting to length

-

To determine length required, set implement in closest working

position (L2) to tractor, hold driveshaft halves side by side and mark

off.

Important!

•

Note the maximum

operating length (L1)

-

Try to attain the

greatest possible

shaft over-

lap (min.

1

/

2

X)!

•

Shorten inside and

outside tube guard

by the same amount.

•

Fit torque limiter (2) of drive

shaft to implement end of

driveshaft!

•

Always check that drive shaft

locks are securely engaged

before starting work.

Retaining chain

-

Use chain to prevent tube guard

from rotating.

Take care that chain does not

impede driveshaft pivoting.

Rules for working

Never exceed the maximum p. t. o.

speed when using the implement.

-

When the p.t.o. is switched off,

the implement hitched up may not stop at once.

Do not go close to the implement until all motion has stopped; only

then may work be done on it.

-

When the implement ist

parked, either remove the

driveshaft and store it, or

secure it with a chain. (Do not

use retaining chain (H) for this).

X

X

L1

L2

X

X

min.

TD 52/97/37

- B 1 -

8

h

FETT

L

L

K92E,K92/4E

K90,K90/4,K94/1