11

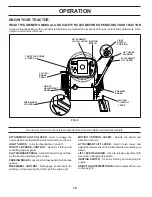

OPERATION

The operation of any tractor can result in foreign objects thrown into the eyes, which can

result in severe eye damage. Always wear safety glasses or eye shields while operating

your tractor or performing any adjustments or repairs. We recommend a wide vision

safety mask over spectacles or standard safety glasses.

IMPORTANT: LEAVING THE IGNITION SWITCH IN ANY

POSITION OTHER THAN "OFF" WILL CAUSE THE

BATTERY TO BE DISCHARGED, (DEAD).

NOTE: Under certain conditions when tractor is standing idle

with the engine running, hot engine exhaust gases may

cause “browning” of grass. To eliminate this possibility,

always stop engine when stopping tractor on grass areas.

CAUTION: Always stop tractor com-

pletely, as described above, before leav-

ing the operator's position; to empty

grass catcher, etc.

HOW TO USE YOUR TRACTOR

TO SET PARKING BRAKE (See Fig. 6)

Your tractor is equipped with an operator presence sensing

switch. When engine is running, any attempt by the operator

to leave the seat without first setting the parking brake will

shut off the engine.

•

Depress clutch/brake pedal into full “BRAKE” position

and hold.

•

Place parking brake lever in “ENGAGED” position and

release pressure from clutch/brake pedal. Pedal should

remain in “BRAKE” position. Make sure parking brake

will hold tractor secure.

STOPPING (See Fig. 6)

MOWER BLADES -

•

To stop mower blades,move attachment clutch lever to

“DISENGAGED” position.

GROUND DRIVE -

•

To stop ground drive, depress clutch/brake pedal into

full “BRAKE” position.

•

Move motion control lever to neutral (N) position.

IMPORTANT:

THE MOTION CONTROL LEVER DOES

NOT RETURN TO NEUTRAL (N) POSITION WHEN THE

CLUTCH/BRAKE PEDAL IS DEPRESSED.

ENGINE -

•

Move throttle control to slow position.

NOTE: Failure to move throttle control to slow position and

allowing engine to idle before stopping may cause engine to

“backfire”.

•

Turn ignition key to “OFF” position and remove key.

Always remove key when leaving tractor to prevent

unauthorized use.

•

Never use choke to stop engine.

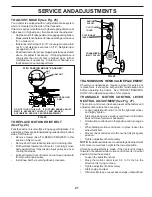

PARKING BRAKE

"ENGAGED"

POSITION

MOTION

CONTROL

LEVER

THROTTLE/CHOKE

CONTROL LEVER

IGNITION KEY

"DISENGAGED"

POSITION

ATTACHMENT CLUTCH LEVER

"ENGAGED" POSITION

"BRAKE"

POSITION

CLUTCH/BRAKE

PEDAL "DRIVE"

POSITION

PARKING BRAKE

"DISENGAGED"

POSITION

FIG. 6

HEIGHT

ADJUSTMENT

KNOB

TO MOVE FORWARD AND BACKWARD (See

Fig. 6)

The direction and speed of movement is controlled by the

motion control lever.

•

Start tractor with motion control lever in neutral (N)

position.

•

Release parking brake and clutch/brake pedal.

•

Slowly move motion control lever to desired position.

TO USE THROTTLE CONTROL (See Fig. 6)

Always operate engine at full throttle.

•

Operating engine at less than full throttle reduces the

battery charging rate.

•

Full throttle offers the best bagging and mower perfor-

mance.

TO ADJUST MOWER CUTTING HEIGHT (See

Fig. 6)

The cutting height is controlled by turning the height adjust-

ment knob in desired direction.

•

Turn knob clockwise (

) to raise cutting height.

•

Turn knob counterclockwise (

) to lower cutting

height.

The cutting height range is approximately 1-1/2" to 4". The

heights are measured from the ground to the blade tip with

the engine not running. These heights are approximate and

may vary depending upon soil conditions, height of grass

and types of grass being mowed.

•

The average lawn should be cut to approximately 2-1/2

inches during the cool season and to over 3 inches

during hot months. For healthier and better looking

lawns, mow often and after moderate growth.

•

For best cutting performance, grass over 6 inches in

height should be mowed twice. Make the first cut

relatively high; the second to desired height.

Summary of Contents for 173304

Page 44: ...44 SERVICE NOTES ...

Page 45: ...45 SERVICE NOTES ...