2

Safe Operation Practices for Snow Throwers

IMPORTANT:

This machine is capable of amputating hands and feet and throwing objects. Failure to observe the following

safety instructions could result in serious injury or death.

SAFETY RULES

WARNING: This snow thrower is for

use on sidewalks, driveways and other

ground level surfaces. Caution should

be exercised while using on sloping

surfaces. Do not use snow thrower on

surfaces above ground level such as

roofs of residences, garages, porch es

or other such structures or buildings.

WARNING: Snow throwers have ex-

posed rotating parts, which can cause

severe injury from contact, or from ma-

terial thrown from the discharge chute.

Keep the area of operation clear of all

persons, small children and pets at all

times including startup.

WARNING: Always disconnect spark

plug wire and place it where it can not

con tact plug in order to pre vent ac ci -

den tal start ing when setting up, trans-

port ing, ad just ing or making re pairs.

Look for this symbol to point out im-

por tant safety precautions. It means

CAUTION!!! BE COME ALERT!!! YOUR

SAFE TY IS IN VOLVED.

• Do not operate the equipment without wearing ad e -

quate winter outer garments. Avoid loose, dangling

clothing, such as scarves, which can get caught in

rotating parts. Wear footwear that will improve footing

on slippery surfaces.

• Handle fuel with care; it is highly fl ammable.

-

Never smoke while refueling.

-

Use an approved fuel container.

-

Never remove fuel tank cap or add fuel to a running

engine (motor) or hot engine (motor).

-

Fill fuel tank outdoors with extreme care. Never fi ll

fuel tank indoors.

-

Replace fuel cap securely and wipe up spilled

fuel.

-

Never store fuel or snow thrower with fuel in the

tank inside of a building where fumes may reach

an open fl ame or spark.

-

Check fuel supply before each use, allowing space

for expansion as the heat of the engine (motor)

and/or sun cause fuel to expand.

STATIC ELECTRICITY HAZARD -

-

Never fi ll containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

con tain ers on the ground, away from your vehicle

before fi lling.

-

When practical, remove gas-powered equipment

from the truck or trailer and refuel it on the ground.

If this is not possible, then refuel such equipment

on a trailer with a portable container, rather than

from a gasoline dispenser nozzle.

-

Keep the nozzle in contact with the rim of the fuel

tankopening at all times, until re fu el ing is complete.

Do not use a nozzle lock-open device.

-

If fuel is spilled on clothing, change clothing im-

me di ate ly.

• For all units with electric starting motors use electric

starting ex ten sion cords certifi ed CSA/UL. Use only

with a receptacle that has been installed in accordance

with local inspection authorities.

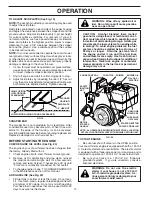

• If snow thrower must be operated over gravel surface,

use extra caution and be sure skid plates are adjusted

to lowest (highest scraper clear ance) position.

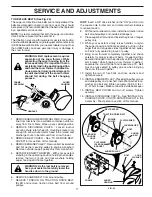

• Never attempt to make any ad

just ments while the

engine (motor) is running (except when specifi cally

rec om mend ed by manufacturer).

• Let engine (motor) and snow thrower adjust to outdoor

temperatures before starting to clear snow.

• Always wear safety glasses or eye shields during op-

eration or while performing an adjustment or repair to

protect eyes from foreign objects that may be thrown

from the snow thrower.

OPERATION

• Do not operate this machine if you are under the infl u-

ence of alcohol or taking drugs or other medication

which can cause drowsiness or affect your ability to

operate this ma chine.

• Do not use this machine if you are mentally or phys i cal ly

unable to operate this machine safely.

TRAINING

• Read the operating and service instruction manual

care ful ly. Be thoroughly familiar with the controls and

the proper use of the equipment. Know how to stop the

unit and disengage the controls quickly.

• Never allow children to operate the equipment. Never

allow adults to operate the equipment without proper

instruction.

• Keep the area of operation clear of all persons, par-

tic u lar ly small children and pets.

• Exercise caution to avoid slipping or falling especially

when operating in reverse.

PREPARATION

• Remove foreign objects. Thoroughly inspect the area

where the equip ment is to be used and remove all

doormats, sleds, boards, wires, rocks & landscaping.

• Disengage all clutches before starting engine (mo-

tor).

CAUTION: Muffl er and other engine

parts become extremely hot during

operation and remain hot after engine

has stopped. To avoid severe burns on

contact, stay away from these areas.

WARNING: Engine exhaust, some of

its con

stit u ents, and certain vehicle

com po nents contain or emit chem

i-

cals known to the State of Cal i for nia

to cause can cer and birth defects or

oth er re pro duc tive harm.