19

SERVICE AND ADJUSTMENTS

00598

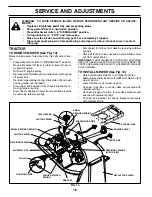

TO LEVEL MOWER HOUSING

Adjust the mower while tractor is parked on level ground

or driveway. Make sure tires are properly infl ated (See

“PROD UCT SPECIFICATIONS” section of this manual). If

tires are over or underinfl ated, you will not properly adjust

your mower.

SIDE-TO-SIDE ADJUSTMENT (See Figs. 14 and 15)

• Raise mower to its highest position.

• At the midpoint of both sides of mower, measure height

from bot tom edge of mower to ground. Distance “A”

on both sides of mower should be the same or within

1/4" of each other.

• If adjustment is necessary, make adjustment on one

side of mower only.

• To raise one side of mower, tighten lift link ad just ment

nut on that side.

• To lower one side of mower, loosen lift link ad just ment

nut on that side.

NOTE

: Three full turns of adjustment nut will change mower

height about 1/8".

• Recheck measurements after adjusting.

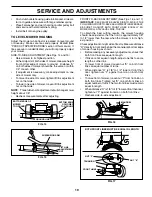

01156

NUT "E"

01268

"D"

"D"

MANDREL

FIG. 16

NUT "F"

FRONT LINKS

FIG. 17

FRONT-TO-BACK ADJUSTMENT (See Figs. 16 and 17)

IMPORTANT:

DECK MUST BE LEVEL SIDE-TO-SIDE. IF THE

FOLLOWING FRONT-TO-BACK ADJUSTMENT IS NECESSARY,

BE SURE TO AD JUST BOTH FRONT LINKS EQUAL LY SO

MOWER WILL STAY LEVEL SIDE-TO-SIDE.

To obtain the best cutting results, the mower housing

should be adjusted so that the front is approximately 1/8"

to 1/2" lower than the rear when the mower is in its high-

est position.

Check adjustment on right side of tractor. Measure dis tance

“D” directly in front and behind the mandrel at bottom edge

of mower housing as shown.

• Before making any necessary adjustments, check that

both front links are equal in length.

• If links are not equal in length, adjust one link to same

length as other link.

• To lower front of mower loosen nut “E” on both front

links an equal number of turns.

• When distance “D” is 1/8" to 1/2" lower at front than

rear, tighten nuts “F” against trunnion on both front

links.

• To raise front of mower, loosen nut “F” from trunnion on

both front links. Tighten nut “E” on both front links an

equal number of turns. The two front links must remain

equal in length.

• When distance “D” is 1/8" to 1/2" lower at front than rear,

tighten nut “F” against trunnion on both front links.

• Recheck side-to-side adjustment.

BOTH FRONT LINKS MUST BE EQUAL IN LENGTH

01267

FIG. 14

01553

SUSPENSION ARM

LIFT LINK

ADJUSTMENT

NUT

FIG. 15

“A”

“A”

BOTTOM EDGE OF

MOWER

TO GROUND

BOTTOM EDGE

OF MOWER

TO GROUND

GROUND LINE

TRUNNION

• Push clutch cable housing guide into bracket, slide col-

lar onto guide and secure with large retainer spring.

• Place fl at washer and clutch spring on idler pulley bolt

and secure with small retainer spring.

• Install belt onto engine pulley.

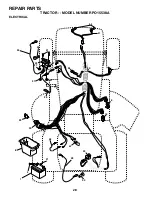

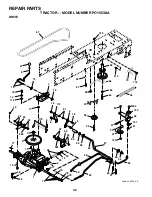

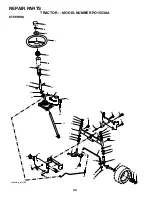

Summary of Contents for 188695

Page 44: ......