5

ASSEMBLY

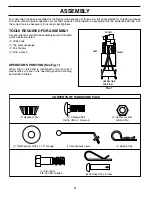

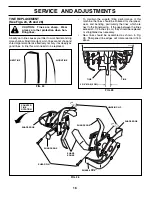

VIEWED FROM R.H. SIDE OF TILLER

• Grasp handle assembly. Hold in “up” position. Be sure

handle lock remains in gearcase notch. Slide handle

assembly into position.

HANDLE ASSEMBLY

"UP" POSITION

FIG. 4

UNPACKING CARTON (See Fig. 2)

CAUTION: Be careful of exposed

sta ples when handling or disposing

of cartoning material.

IMPORTANT:

WHEN UN

PACK ING AND AS

SEM BLING

TILLER, BE CAREFUL NOT TO STRETCH OR KINK CABLES.

• While holding handle assembly, cut cable ties se cur ing

handle assembly to top frame. Let handle assembly

rest on tiller.

• Remove top frame of carton.

• Slowly ease handle assembly up and place on top of

carton.

• Cut down right hand front and right hand rear cor ners

of carton, lay side carton wall down.

• Remove packing material from handle assembly.

FIG. 2

cart

on_2

SHIFT ROD

HANDLE

AS SEM BLY

INSTALL HANDLE (See Figs. 3, 4, and 5)

• Insert one handle lock (with teeth facing outward) in

gearcase notch. (Apply grease on smooth side of

handle lock to aid in keeping lock in place until handle

assembly is lowered into position.)

FIG. 3

GEARCASE

NOTCH

HANDLE ASSEMBLY

HANDLE

LOCK

LOOSEN HANDLE

LOCK LEVER TO

MOVE

TIGHTEN HANDLE

LOCK LEVER TO

HOLD

handles_34

FLAT

WASHER

CARRIAGE

BOLT

GEARCASE

LOCKNUTS

PIVOT BOLT

HANDLE

LOCK

SLOT

HANDLE

BASE

FIG. 5

• Rotate handle assembly down. Insert rear carriage bolt

fi rst, with bolt head on L.H. side of tiller and loosely

assemble locknut (See Fig. 5).

• Insert pivot bolt in front part of plate and tighten.

• Cut down remaining corners of carton and lay panels

fl at.

• Lower the handle assembly. Tighten nut on carriage

bolt bolt so handle moves with some resistance. This

will allow for easier adjustment.

• Place fl at washer on threaded end of handle lock le-

ver.

• Insert handle lock lever through handle base and

gearcase. Screw in handle lock lever just enough to

hold lever in place.

• Insert second handle lock (with teeth in ward) in the

slot of the handle base (just inside of washer).

• With handle assembly in lowest position, securely

tight en handle lock lever by rotating clockwise. Leav-

ing handle assembly in lowest position will make it

easier to remove tiller from carton.

HANDLE

LOCK LEVER