7

OPERATION

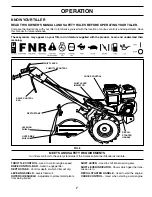

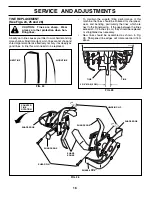

KNOW YOUR TILLER

READ THIS OWNER'S MANUAL AND SAFETY RULES BEFORE OPERATING YOUR TILLER.

Compare the illustrations with your tiller to familiarize yourself with the location of various controls and adjustments. Save

this manual for future reference.

These symbols may appear on your Tiller or in literature supplied with the product. Learn and understand their

meaning.

CHOKE CONTROL

DEPTH STAKE

RECOIL

STARTER

HANDLE

LEVELING

SHIELD

DRIVE CONTROL

BAR

THROTTLE CON TROL

SHIFT LEVER

OUTER SIDE

SHIELD

FIG. 8

MEETS ANSI SAFETY REQUIREMENTS

Our tillers conform to the safety standards of the American National Standards Institute.

SHIFT LEVER

- Used to shift transmission gears.

SHIFT LEVER INDICATOR

- Shows which gear the trans-

mis sion is in.

RECOIL STARTER HANDLE

- Used to start the engine.

CHOKE CONTROL

- Used when starting a cold engine.

THROTTLE CONTROL

- Used to con trol engine speed.

DRIVE CONTROL BAR

- Used to engage tiller.

DEPTH STAKE

- Controls depth at which tiller will dig.

LEVELING SHIELD

- Levels tilled soil.

OUTER SIDE SHIELD

- Adjustable to protect small plants

from being buried.

SHIFT LEVER

INDICATOR