24

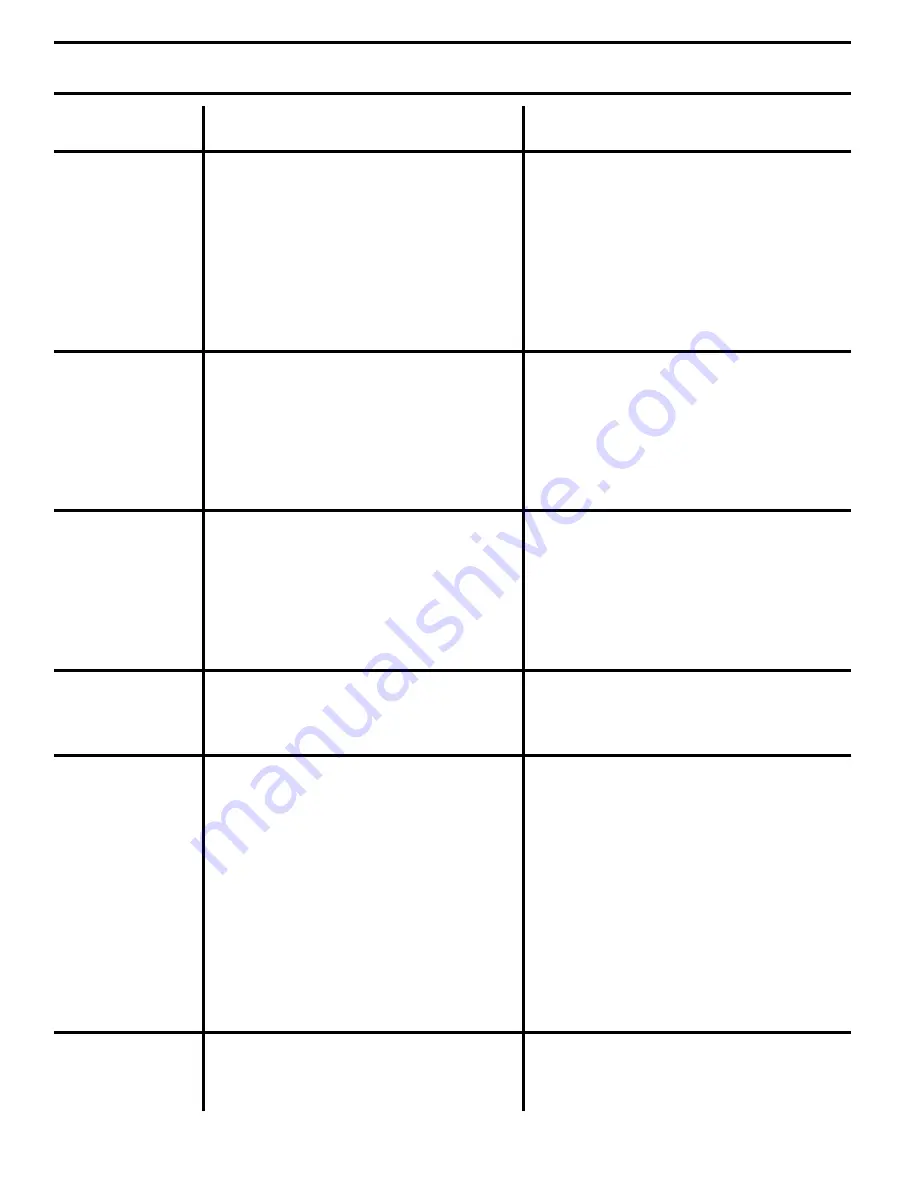

TROUBLESHOOTING POINTS

Will not start

1. Out of fuel. 1. Fill fuel tank.

2. Engine not “CHOKED” properly. 2. See “TO START ENGINE” in Operation section.

3. Engine fl ooded. 3. Wait several minutes before attempting to start.

4. Bad spark plug. 4. Replace spark plug.

5. Dirty air fi lter. 5. Clean/replace air fi lter.

6. Dirty fuel fi lter. 6. Replace fuel fi lter.

7. Water in fuel. 7. Empty fuel tank and carburetor, refi ll tank with fresh

gasoline and replace fuel fi lter.

8. Loose or damaged wiring. 8. Check all wiring.

9. Carburetor out of adjustment. 9. See “To Adjust Carburetor” in Service Adjustments

section.

10. Engine valves out of adjustment. 10. Contact an authorized service center/department.

Hard to start

1. Dirty air fi lter. 1. Clean/replace air fi lter.

2. Bad spark plug. 2. Replace spark plug.

3. Weak or dead battery. 3. Recharge or replace battery.

4. Dirty fuel fi lter. 4. Replace fuel fi lter.

5. Stale or dirty fuel. 5. Empty fuel tank and refi ll tank with fresh, clean gasoline.

6. Loose or damaged wiring. 6. Check all wiring.

7. Carburetor out of adjustment. 7. See “To Adjust Carburetor” in Service Adjustments

section.

8. Engine valves out of adjustment. 8. Contact an authorized service center/department.

Engine will not turn over

1. Clutch/brake pedal not depressed. 1. Depress clutch/brake pedal.

2. Attachment clutch is engaged. 2. Disengage attachment clutch.

3. Weak or dead battery. 3. Recharge or replace battery.

4. Blown fuse. 4. Replace fuse.

5. Corroded battery terminals. 5. Clean battery terminals.

6. Loose or damaged wiring. 6. Check all wiring.

7. Faulty ignition switch. 7. Check/replace ignition switch.

8. Faulty solenoid or starter. 8. Check/replace solenoid or starter.

9. Faulty operator presence switch(es). 9. Contact an authorized service center/department.

Engine clicks but will not

1. Weak or dead battery. 1. Recharge or replace battery.

start

2. Corroded battery terminals. 2. Clean battery terminals.

3. Loose or damaged wiring. 3. Check all wiring.

4. Faulty solenoid or starter. 4. Check/replace solenoid or starter.

Loss of power

1. Cutting too much grass/too fast. 1. Raise cutting height/reduce speed.

2. Throttle in “CHOKE” position. 2. Adjust throttle control.

3. Build-up of grass, leaves and trash under mower. 3. Clean underside of mower housing.

4. Dirty air fi lter. 4. Clean/replace air fi lter.

5. Low oil level/dirty oil. 5. Check oil level/change oil.

6. Faulty spark plug. 6. Clean and regap or change spark plug.

7. Dirty fuel fi lter. 7. Replace fuel fi lter.

8. Stale or dirty fuel. 8. Empty fuel tank and refi ll tank with fresh, clean gasoline.

9. Water in fuel. 9. Empty fuel tank and carburetor, refi ll tank with fresh

gasoline and replace fuel fi lter.

10. Spark plug wire loose. 10. Connect and tighten spark plug wire.

11. Dirty engine air screen/fi ns. 11. Clean engine air screen/fi ns.

12. Dirty/clogged muffl er. 12. Clean/replace muffl er.

13. Loose or damaged wiring. 13. Check all wiring.

14. Carburetor out of adjustment. 14. See “To Adjust Carburetor” in Service Adjustments

section.

15. Engine valves out of adjustment. 15. Contact an authorized service center/department.

Excessive vibration

1. Worn, bent or loose blade. 1. Replace blade. Tighten blade bolt.

2. Bent blade mandrel. 2. Replace blade mandrel.

3. Loose/damaged part(s). 3. Tighten loose part(s). Replace damaged parts.

PROBLEM

CAUSE

CORRECTION