18

SERVICE AND ADJUSTMENTS

WARNING: TO AVOID SE

RI OUS IN

JU RY, BEFORE PERFORMING ANY SERVICE OR ADJUST-

MENTS:

•

Depress clutch/brake pedal fully and set parking brake.

•

Place gearshift lever in neutral (N) position.

•

Place attachment clutch in “DISENGAGED” position.

•

Turn ignition key to “STOP” and remove key.

•

Make sure the blades and all moving parts have completely stopped.

•

Disconnect spark plug wire from spark plug and place wire where it cannot come in contact

with

plug.

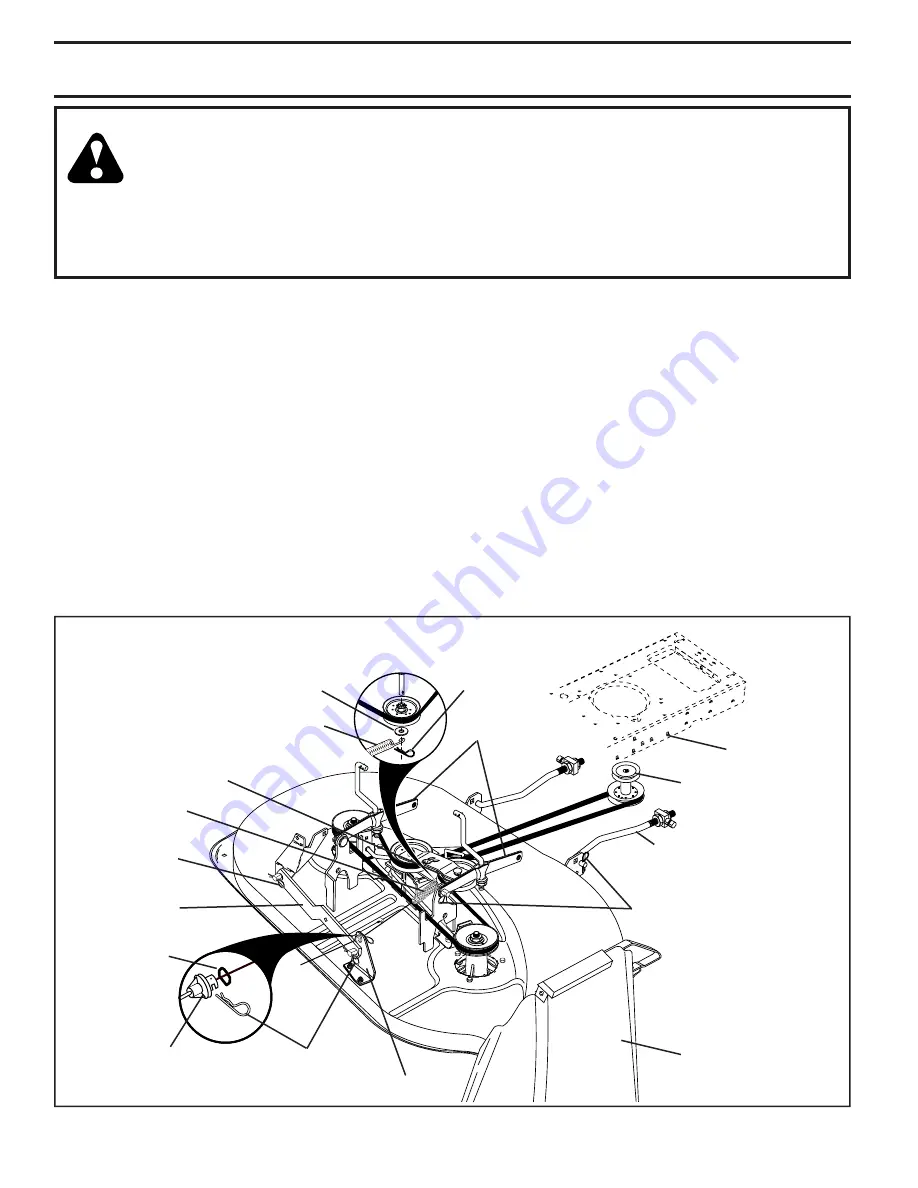

TRACTOR

38

42

02695

SUSPENSION ARMS

RETAINER SPRING

ANTI-SWAY BAR

HOUSING GUIDE

COLLAR

LARGE RE TAIN ER

SPRING

CLUTCH SPRING

SMALL RETAINER SPRING

BRACKET

RETAINER SPRINGS

(BOTH SIDES)

FRONT LINK

ENGINE PULLEY

SQUARE HOLE

TO REMOVE MOWER (See Fig. 13)

Mower will be easier to remove from the right side of trac-

tor.

• Place attachment clutch in “DIS EN GAGED” position.

• Move attachment lift lever forward to low er mower to

its lowest po si tion.

• Roll belt off engine pulley.

• Remove small retainer spring, and remove clutch spring

off pulley bolt.

• Remove large retainer spring, slide col lar off and push

housing guide out of brack et.

• Disconnect anti-swaybar from chas sis bracket by re-

mov ing re tain er spring.

• Disconnect suspension arms from rear deck brackets

by removing retainer springs.

• Disconnect front links from deck by re mov ing retainer

springs.

• Raise lift lever to raise suspension arms. Slide mower

out from under tractor.

IMPORTANT:

IF AN ATTACHMENT OTHER THAN THE MOWER

DECK IS TO BE MOUNTED ON THE TRAC TOR, REMOVE THE

FRONT LINKS AND HOOK THE CLUTCH SPRING INTO SQUARE

HOLE IN FRAME.

TO INSTALL MOWER (See Fig. 13)

• Raise attachment lift lever to its high est position.

• Slide mower under tractor with defl ector shield to right

side of tractor.

• Lower lift lever to its lowest po si tion.

• Connect front links to mower deck and secure with

retainer springs.

• Connect suspension arms to rear deck brackets and

secure with retainer springs.

• Connect anti-swaybar to chassis bracket and secure

with retainer spring.

DEFLECTOR SHIELD

CLUTCH SPRING

FLAT WASHER

SMALL

RETAINER SPRING

FIG. 13

Summary of Contents for 192666

Page 28: ......