24

TO REPLACE HEADLIGHT BULB

1. Raise hood.

2. Pull bulb holder out of the hole in the

backside of the grill.

3. Replace bulb in holder and push bulb

holder securely back into the hole in

the backside of the grill.

4. Close hood.

INTERLOCKS AND RELAYS

Loose or damaged wiring may cause

your tractor to run poorly, stop running, or

prevent it from starting.

• Check wiring. See electrical wiring

diagram in the Repair Parts section.

TO REPLACE FUSE

Replace with 20 amp automotive-type

plug-in fuse. The fuse holder is located

behind the dash.

TO REMOVE HOOD AND GRILL AS-

SEMBLY

1. Raise hood.

2. Unsnap headlight wire connector.

3. Stand in front of tractor. Grasp hood at

sides, tilt toward engine and lift off of

tractor.

4. When replacing hood, be sure to re-

connect the headlight wire con nec tor.

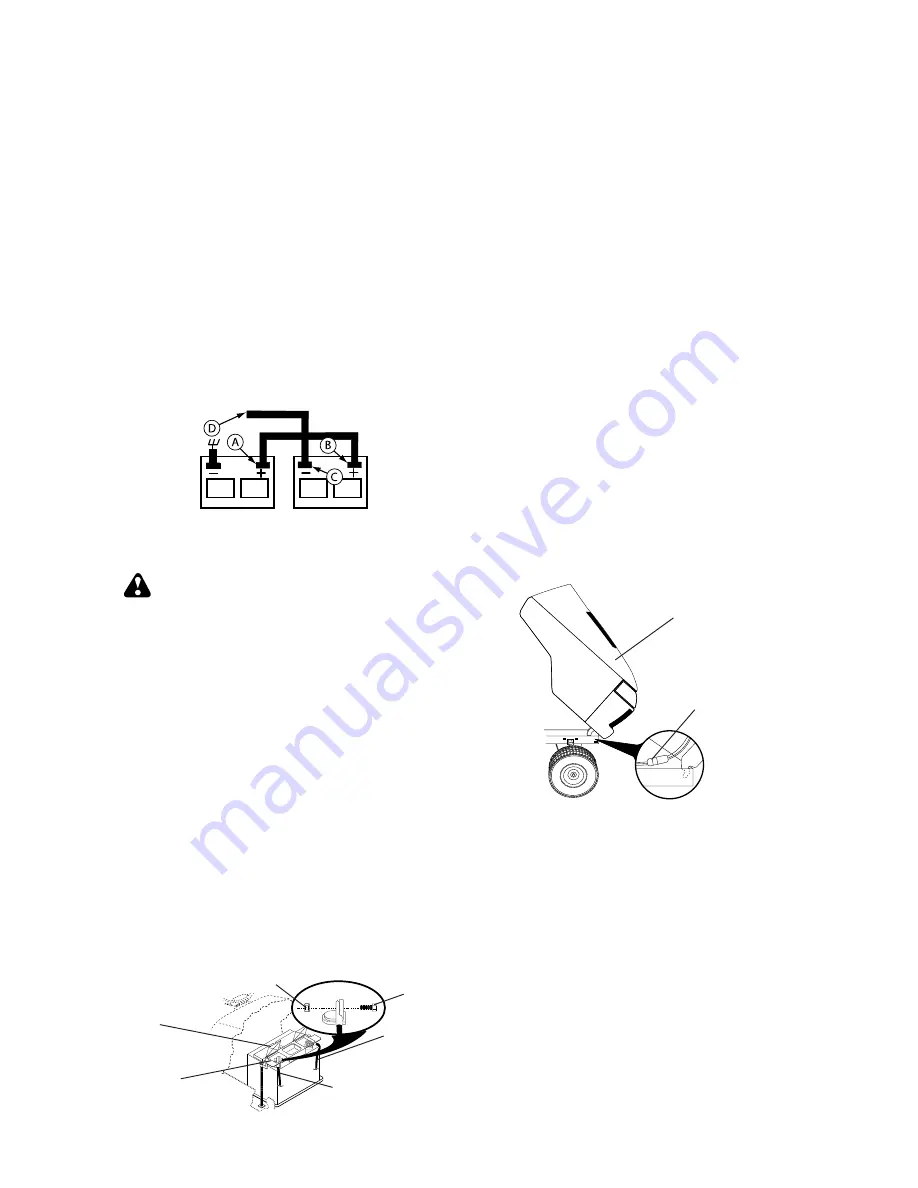

02141

Headlight Wire

Connector

Hood

ENGINE

TO AD JUST THROTTLE CON TROL

CABLE

The throttle control has been preset at the

factory and ad just ment should not be nec-

essary. Check adjustment as described

below before loosening cable. If adjust-

ment is necessary, see engine manual

TO AD JUST CARBURETOR

The carburetor has been preset at the

factory and ad just ment should not be nec-

essary. However, minor ad just ment may

be required to compensate for dif fer enc es

in fuel, temperature, altitude or load. If

the carburetor does need ad just ment, see

engine manual.

0217

9

Keps Nut

Terminal

Guard

Terminal

Access

Door

Hex Bolt

Positive

(Red)

Cable

Negative (Black)

Cable

REPLACING BATTERY

WARNING:

Do not short battery ter mi -

nals by allowing a wrench or any other object

to contact both terminals at the same time.

Before connecting battery, remove metal

bracelets, wristwatch bands, rings, etc.

Positive terminal must be connected fi rst to

prevent sparking from ac ci den tal grounding.

1. Lift hood to raised position.

2. Remove terminal guard.

3. Disconnect BLACK battery cable

then RED battery cable and carefully

remove battery from tractor.

4. Install new battery with terminals in

same position as old battery.

5. Reinstall terminal guard.

6. First connect RED battery cable to posi-

tive (+) battery terminal with hex bolt and

keps nut as shown. Tighten securely.

7. Connect BLACK grounding cable to neg-

ative (-) bat tery terminal with re main ing

hex bolt and keps nut. Tight en securely

8. Close terminal access doors.

9. Close hood.

02614

Weak or Dead

Battery

Fully Charged

Battery

IMPORTANT

: Your tractor is equipped

with a 12 volt system. The other vehicle

must also be a 12 volt system. Do not use

your tractor battery to start other vehicles.

TO ATTACH JUMPER CABLES -

1. Connect one end of the RED cable

to the POSITIVE (+) terminal of each

battery(A-B), taking care not to short

against tractor chassis.

2. Connect one end of the BLACK ca ble

to the NEGA TIVE (-) terminal (C) of

fully charged battery.

3. Connect the other end of the BLACK

cable (D) to good chassis ground,

away from fuel tank and bat tery.

TO REMOVE CABLES, REVERSE ORDER

1. BLACK cable fi rst from chassis and

then from the fully charged battery.

2. RED cable last from both batteries.