20

SERVICE AND ADJUSTMENTS

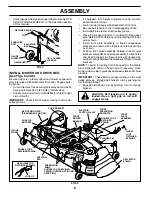

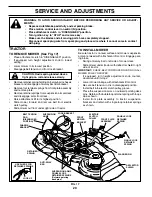

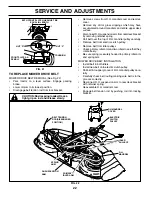

FIG. 17

TRACTOR

WARNING: TO AVOID SERIOUS INJURY, BEFORE PERFORMING ANY SER

VICE OR AD

JUST -

MENTS:

•

Depress clutch/brake pedal fully and set parking brake.

•

Place motion control lever in neutral (N) position.

•

Place attachment clutch in “DISENGAGED” position.

•

Turn ignition key to “STOP” and remove key.

•

Make sure the blades and all moving parts have completely stopped.

•

Disconnect spark plug wire from spark plug and place wire where it cannot come in contact

with

plug.

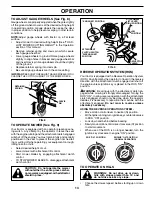

TO REMOVE MOWER (See Fig. 17)

• Place attachment clutch in “DIS EN GAGED” position.

• If equipped, turn height adjustment knob to low

est

set ting.

• Lower mower to its lowest position.

• Disengage belt tension rod from lock bracket.

CAUTION: Rod is spring loaded. Have a

tight grip on rod and release slowly.

02565

SUSPENSION

ARMS

RETAINER

SPRING

ANTI-SWAY

BAR

SUSPENSION ARMS

DOUBLE LOOP

RETAINER SPRINGS

(Out ward pointing

deck pins)

CHASSIS

BRACK ET

SINGLE LOOP

RETAINER

SPRING

FRONT

MOWER

BRACKET

FLANGED PIN

ELECTRIC

CLUTCH

PULLEY

FRONT PLATE

AS SEM BLY

BELT TEN SION

ROD

(DISENGAGED

POSITION)

• Remove retainer spring holding anti-swaybar to chas sis

bracket and dis en gage anti-swaybar from bracket.

• Remove four retainer springs from front plate assembly

and remove plate.

• Remove retainer springs from sus pen sion arms at deck

and dis en gage arms from deck.

• Raise attachment lift to its highest position.

• Slide mower forward and remove belt from electric

clutch pulley.

• Slide mower out from under right side of tractor.

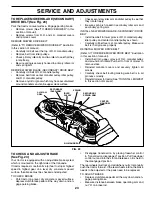

TO INSTALL MOWER

Be sure tractor is on level surface and mower suspension

arms are raised with attachment lift control. Engage park-

ing brake.

• Swing anti-sway bar to left side of mower deck.

• Slide mower under tractor with defl ector shield to right

side of tractor.

IMPORTANT:

CHECK BELT FOR PROPER ROUTING IN ALL

MOWER PULLEY GROOVES.

• If equipped, turn height ad just ment knob coun

ter -

clock wise until it stops.

• Lower mower linkage with attachment lift control.

• Be sure belt tension rod is in dis en gaged position.

• Install belt into electric clutch pulley groove.

• Place the suspension arms on outward pointing deck

pins. Retain with double loop re tain er spring with loops

up as shown.

• Install front plate assembly to tractor suspension

brack ets and retain with single loop retainer springs

as shown.

DOUBLE LOOP

RETAINER

SPRING

DEFLECTOR

SHIELD

LOCK BRACK ET

USE PLIERS FOR

RETAINER SPRINGS

LOOP UP