6

ASSEMBLY / PRE-OPERATION

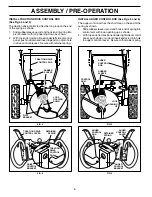

INSTALL TRACTION DRIVE CONTROL ROD

(See Figs. 3 and 4)

The traction drive control rod has the long loop on the end

of the spring as shown.

1. Slide rubber sleeve up rod and hook end of spring into

pivot bracket with loop opening down as shown.

2. With top end of rod positioned under left side of control

panel, push rod down and insert top end of rod into hole

in drive control bracket. Secure with retainer spring.

TRACTION

DRIVE

CON TROL

ROD

DRIVE

CONTROL

BRACKET

RETAINER

SPRING

TRACTION DRIVE

CON TROL LEVER

FIG. 4

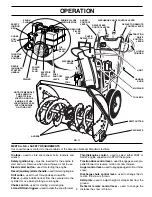

AUGER

CONTROL

LEVER

AUGER

CONTROL

ROD

AUGER

CONTROL

BRACKET

RETAINER

SPRING

FIG. 6

AUGER

CONTROL

ROD

CONTROL

ARM

RUBBER

SLEEVE

LOOP

OPENING

UP

FIG. 5

INSTALL AUGER CONTROL ROD (See Figs. 5 and 6)

The auger control rod has the short loop on the end of the

spring as shown.

1. Slide rubber sleeve up rod and hook end of spring into

control arm with loop opening up as shown.

2. With top end of rod positioned under right side of control

panel, push down on rod and insert end of rod into hole

in auger control bracket. Secure with retainer spring.

TRACTION DRIVE

CONTROL ROD

PIVOT

BRACKET

RUBBER

SLEEVE

LOOP

OPEN ING

DOWN

FIG. 3