Summary of Contents for 270451

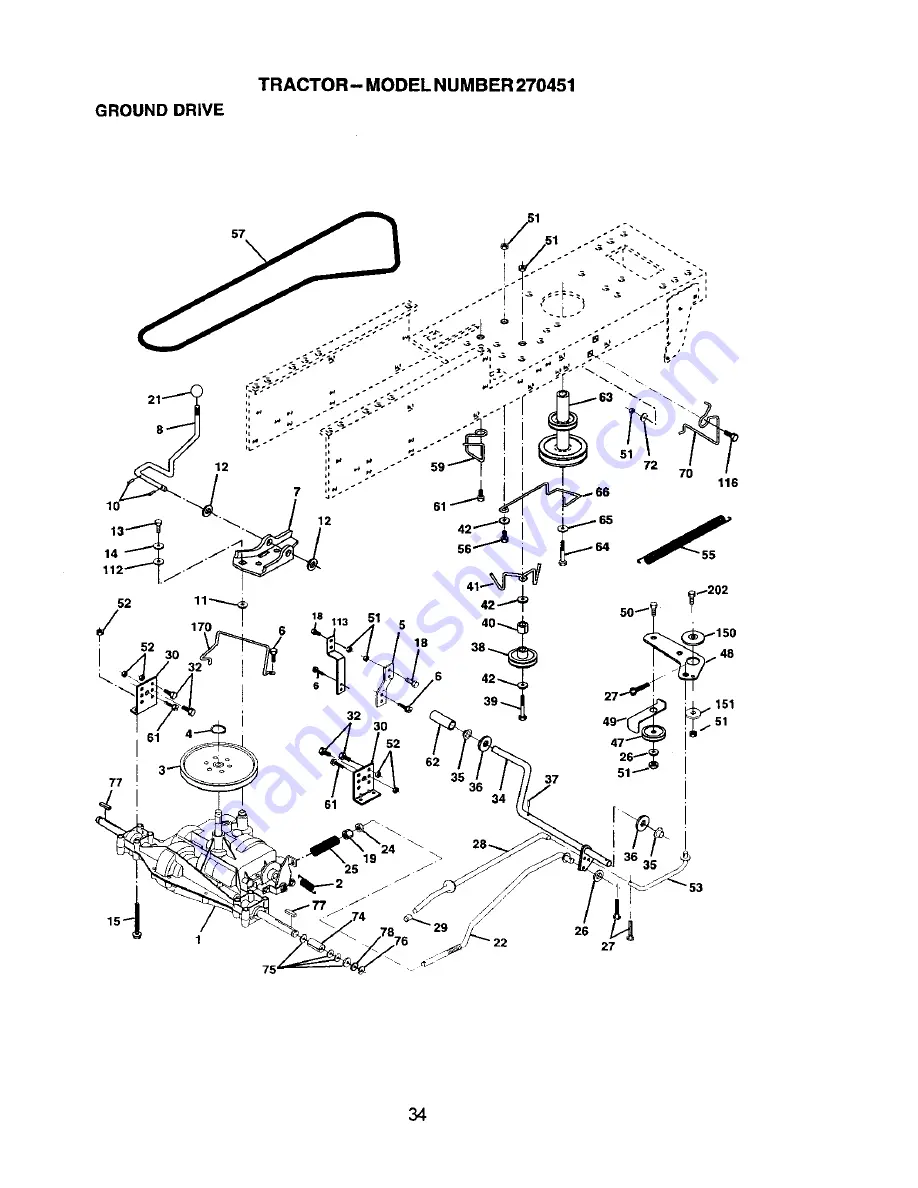

Page 34: ...GROUND DRIVE TRACTOR MODEL NUMBER 270451 29 L J 26 27 34 ...

Page 36: ...STEERING TRACTOR MODEL NUMBER 270451 _41 51 54 4O 25 68 67 67 67 43 36 ...

Page 42: ...MOWER DECK TRACTOR MODEL NUMBER 270451 21 2 14 29 42 ...

Page 45: ...45 ...

Page 46: ...46 ...

Page 48: ...Poulan ...