7

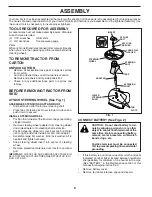

FIG. 2

025

91

DISCARD TERMINAL

PROTECTIVE CAPS

BATTERY

COVER

KEPS

NUT

HEX BOLT

POSITIVE CABLE

(RED)

NEGATIVE

CABLE (BLACK)

ASSEMBLY

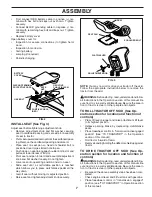

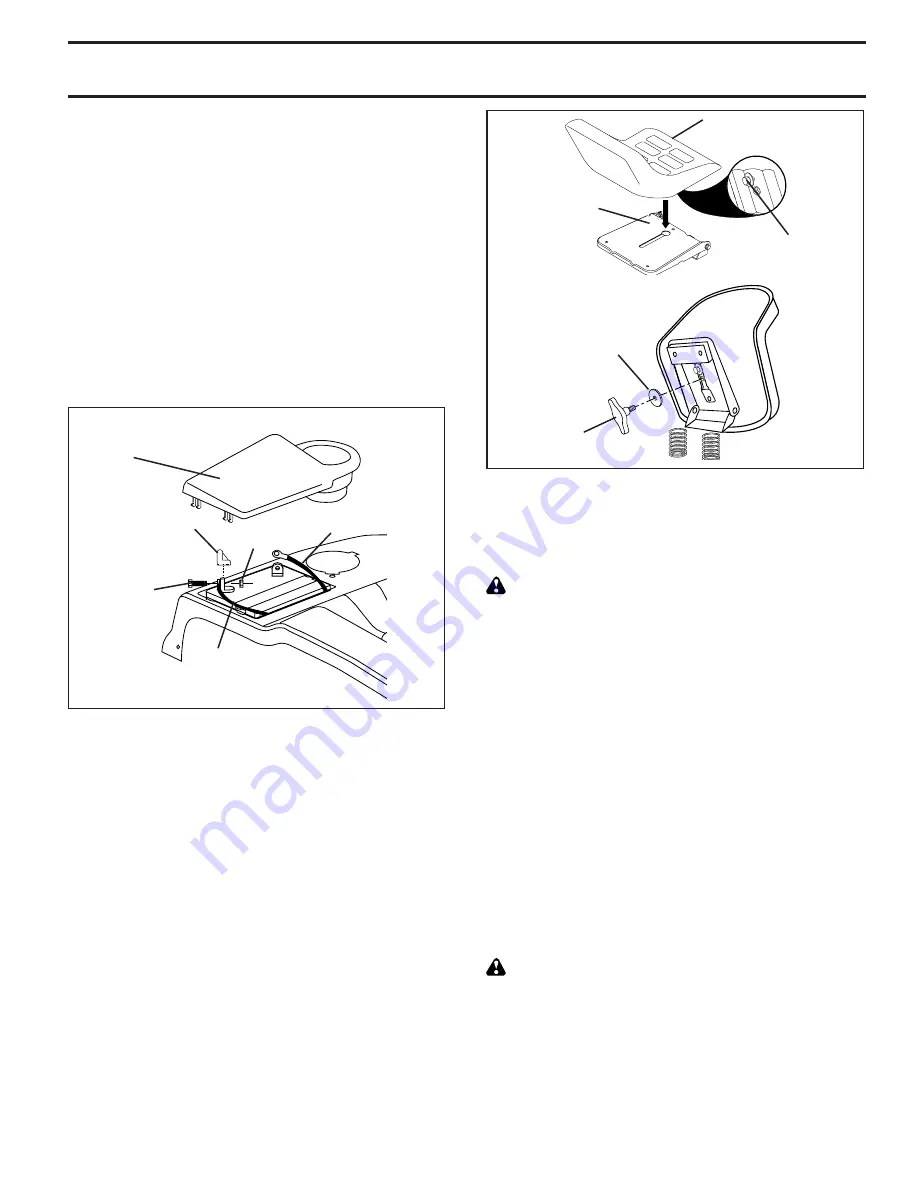

INSTALL SEAT (See Fig. 3)

Adjust seat before tightening adjustment knob.

• Remove adjustment knob and fl at washer securing

seat to cardboard packing and set aside for assembly

of seat to tractor.

• Pivot seat upward and remove from the cardboard pack-

ing. Remove the cardboard packing and discard.

• Place seat on seat pan so head of shoulder bolt is

positioned over large slotted hole in pan.

• Push down on seat to engage shoulder bolt in slot and

pull seat towards rear of tractor.

• Pivot seat and pan forward and assemble adjustment

knob and fl at washer loosely. Do not tighten.

• Lower seat into operating position and sit on seat.

• Slide seat until a comfortable position is reached

which allows you to press clutch/brake pedal all the

way down.

• Get off seat without moving its ad just ed position.

• Raise seat and tighten adjustment knob securely.

FIG. 3

2466

02464

SEAT PAN

SHOUL DER BOLT

AD JUST MENT KNOB

FLAT WASH ER

SEAT

• First connect RED battery cable to positive (+) ter-

minal with hex bolt and keps nut as shown. Tighten

securely.

• Connect BLACK grounding cable to negative (-) ter-

minal with remaining hex bolt and keps nut. Tighten

securely.

• Replace battery cover.

Open battery cover for:

• Inspection for secure connections (to tighten hard-

ware).

• Inspection for corrosion.

• Testing battery.

• Jumping (if required).

• Periodic charging .

NOTE:

You may now roll or drive your tractor off the skid.

Follow the ap pro pri ate instruction below to remove the

tractor from the skid.

WARNING:

Before start ing, read, un der stand and fol low

all in struc tions in the Op er a tion section of this man u al. Be

sure tractor is in a well-ventilated area. Be sure the area in

front of tractor is clear of other peo ple and objects.

TO ROLL TRACTOR OFF SKID (See Op-

er a tion section for location and function of

con trols)

• Press lift lever plunger and raise attachment lift lever

to its highest po si tion.

• Release parking brake by de press ing clutch/brake

ped al.

• Place freewheel control in "trans mis sion dis en gaged

position" (See “TO TRANS

PORT” in the Op

er a tion

section of this manual).

• Roll tractor forward off skid.

• Remove banding holding the defl ector shield up against

tractor.

TO DRIVE TRAC

TOR OFF SKID (See Op-

er a tion section for location and function of

con trols)

WARNING:

Before start ing, read, un der stand and fol low

all in struc tions in the Op er a tion section of this man u al. Be

sure tractor is in a well-ventilated area. Be sure the area in

front of tractor is clear of other peo ple and objects.

• Be sure all the above assembly steps have been com-

pleted.

• Check engine oil level and fi ll fuel tank with gasoline.

• Place freewheel control in "trans

mis sion en

gaged"

po si tion (see "TO TRANSPORT" in Op er a tion section

of this manual).