39

1

- - - - - -

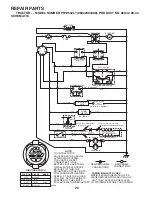

Engine B&S Model No. 31P677

2 137352

Muffler

9

194319

Keeper Belt Engine

12 401985

Pulley

Engine

15

407545

Tank Fuel 1.50

18 197725

Cap

Asm

20 176636X421 Control

Throttle/Choke

21

191611

Screw 10 x 3/4 Single Lead-Hex

28 401137

Fuel

Line

29

137180

Spark Arrester Kit

37 123487X

Clamp

Hose

42

10040700

Washer Lock 7/16

45

73510400

Nut Keps Hex 1/4-20 unc

69 165291

Gasket

79

192334

Screw Socket Hd 5/16-18 x .75

81

148456

Tube Drain Oil Easy

82

181654

Plug Drain Oil

84

17060620

Screw 3/8-16 x 1-1/4

85

173937

Bolt Hex 7/16-20 x 4 x Gr. 5-1.5

90

17000612

Screw 3/8-16 x 1.0

96

19091416

Washer 9/32 x 7/8 x 16 Ga.

97

17670412

Screw 1/4-20 x 3/4

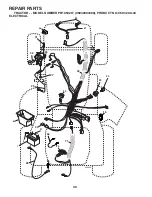

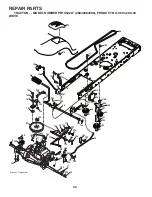

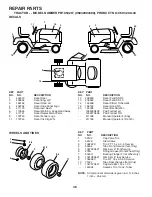

REPAIR PARTS

TRACTOR - - MODEL NUMBER PB19542LT (96042003400), PRODUCT NO. 960 42 00-34

ENGINE

KEY PART

NO. NO.

DESCRIPTION

NOTE:

All component dimensions given in U.S. inches

1 inch = 25.4 mm

Engine Power Rating Information

The gross power rating for individual gas engine models is labeled in accordance with SAE (Society of Automotive Engi-

neers) code J11940 (Small Engine Power & Torque Rating Procedure), and rating performance has been obtained and

corrected in accordance with SAE J1995 (Revision 2002-5). Actual gross engine power will be lower and is affected by,

among other things, ambient operating conditions and engine-to-engine variability. Given both the wide array of prod-

ucts on which engines are placed and the variety of environmental issues applicable to operating the equipment, the

gas engine will not develop the rated gross power when used in a given piece of power equipment (actual “on-site” or

net horsepower). This difference is due to a variety of factors including, but not limited to, accessories (air cleaner, ex-

haust, charging, cooling, carburetor, fuel pump, etc.), application limitations, ambient operating conditions (temperature,

humidity, altitude), and engine-to-engine variability. Due to manufacturing and capacity limitations, Briggs & Stratton

may substitute an engine of higher rated power for this Series engine.