35

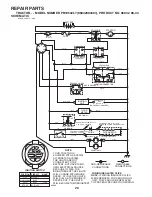

KEY PART

NO. NO.

DESCRIPTION

1

- - - - - -

Transaxle, DANA D6800

2 123583X Key

Square

15

19131316

Washer 13/32 x 13/16 x 16 Ga.

17 197297

Spring,

Brake

22 197660

Rod

Shift

23 409154X421 Knob

26

197455

Spring Brake RTN

29 197267

Rod,

Brake

33 12000001 Ring

E

35

197722

Rod, Brake, Park

37

121749X

Washer 25/32 x 1-1/4 x 16 Ga.

42

8883R

Cover, Foot Pedal

49 72110614 Bolt

50

194327

Pulley Idler Flat

51

73900600

Lock Nut 3/8-16

52 194326

Idler

V-Groove

56 411245

V-Belt,

Drive

61 123666X

Pulley

Transaxle

64

196200

Shaft Asm. Pedal Brake Control

70 193225X428 Console

74

142432

Screw 1/4 x 1/2

116 73900500

Nut Lock Hex Flange 5/16-18

125 17000512

Screw 5/16-18 x 3/4

134 402430

Arm

Shift

139 74550412

Bolt 1/4-20 unf Gr. 8 w/Patch

140 10040400

Washer Lock Hvy Helical 1/4

141 19091210

Washer 9/32 x 3/4 x 10 Ga.

155 12000028

Ring

Retainer

157 105701X

Washer Plate Shf

158 194352

Keeper

T/A

159 76020412

Pin Cotter 1/8 x 3/4

160 169484

Retainer

Clip

161 195403

Spring, Return, Clutch

162 195785

Spacer

165 196212

Busing Shaft Brake Hand Control

166 197290

Nut Push .625

167 405257

Latch Brake Parking

169 74490560

Bolt 5/16-18 x 3.75

172 197657

Strap Torque LH

174 197289

Nut

Push

175 198981

Shaft Asm Shift

176 196214

Arm Clevis Rod Shift

178 197456

Spring

Shift

184 198403X505 Handle Parking Brake

185 72110620

Bolt

186 194321

Spacer

Retainer

187 19133210

Washer

188 194323

Link Clutch Ground Drive

189 194317

Bellcrank Ground Drive

190 194318

Keeper Bellcrank Ground Drive

192 150360

Nut Lock Center 1/4-28

193 17060512

Screw 5/16-18 x 3/4

195 197332

Bracket Brake Rod

202 199589

Link

Shift

203 19111116

Washer 11/32 x 11/16 x 16 Ga.

205 121748X

Washer 25/32 x 1-5/8 x 16 Ga.

276 74780716

Bolt 7/16-14 x 1 Gr.5

277 405296

Washer

Serrated

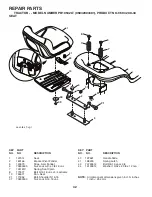

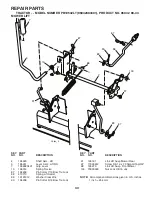

REPAIR PARTS

TRACTOR - - MODEL NUMBER PB19542LT (96042003401), PRODUCT NO. 960 42 00-34

DRIVE

NOTE:

All component dimensions given in U.S. inches

1 inch = 25.4 mm

KEY PART

NO. NO.

DESCRIPTION