17

SERVICE AND ADJUSTMENTS

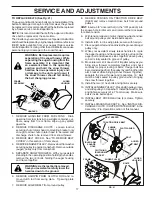

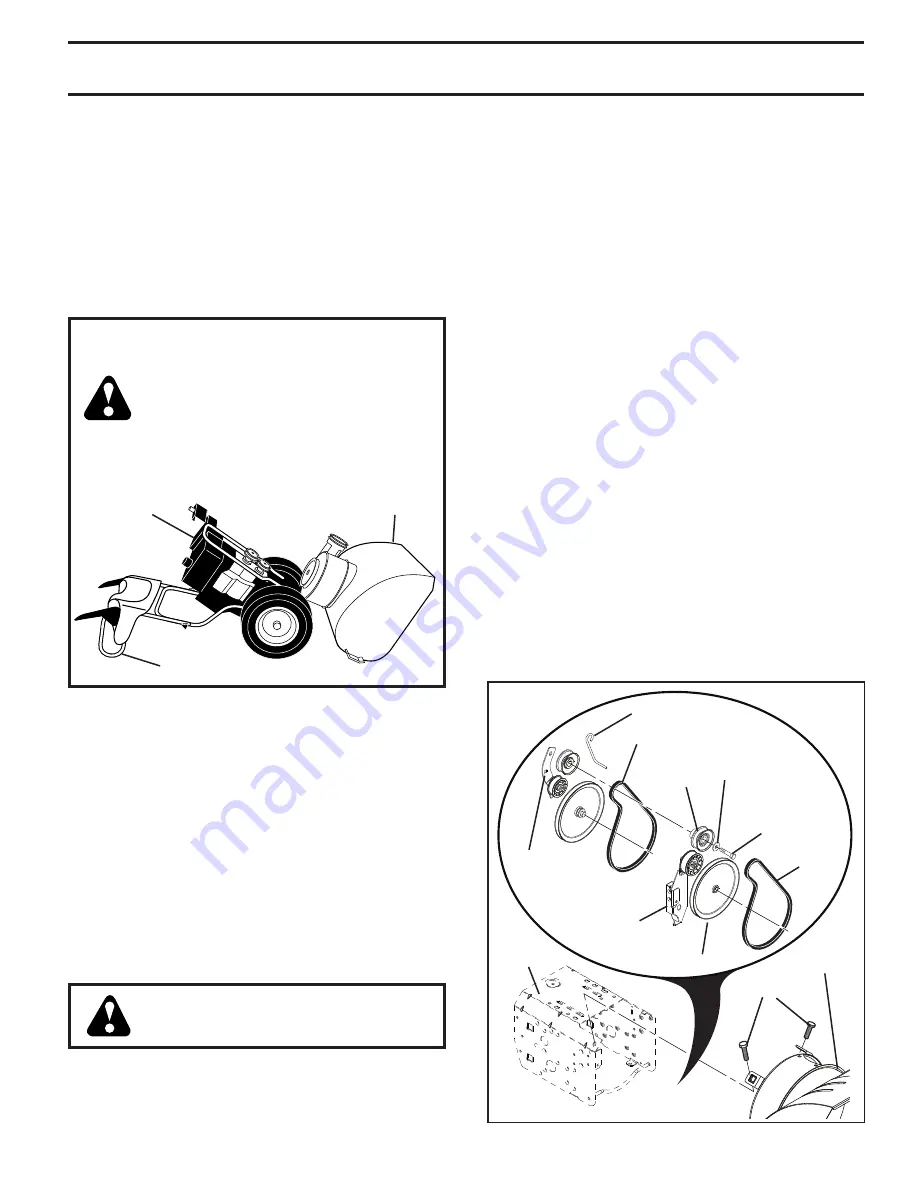

8. RELIEVE TENSION ON TRACTION DRIVE BELT

IDLER and remove traction drive belt from around

pulleys.

HINT:

Insert a 3/8" drive ratchet (in the “ON” position) into

the square hole in idler arm and rotate ratchet clockwise

to relieve tension.

9. With tension relieved on idler, install new traction drive

belt around pulleys and inside belt keepers.

10. Install clutch rod in swing plate; secure with hairpin.

11. Place auger belt around and inside the groove of auger

pulley only.

12. While your assistant slowly raises handles to rejoin

the auger hous ing and frame assembly, pull up on the

auger belt and squeeze sides together above pulley

so belt is fully seated in groove of pulley.

13. Move idler arm so it does not hit impeller pulley as you

bring snow thrower completely together and check

carefully for proper routing of belts. If auger belt has

become dislodged from the pulley (by catching the idler

arm bracket while bringing snow thrower together),

separate the snow thrower and re peat step 12. Belt

must be fully seated in pulley groove when bring ing

the snow thrower together.

14. Install the two (2) hex bolts and tighten securely.

15. INSTALL ENGINE PULLEY - Place belt in pulley groove

and slide pulley on crankshaft. Install flat washer, bolt

and tighten securely (41-47 N-m torque). Make sure

belt is inside belt keeper.

16. INSTALL BELT COVER and two (2) screws. Tighten

securely.

17. INSTALL DISCHARGE CHUTE – See “INSTALL DIS-

CHARGE CHUTE / CHUTE ROTATER HEAD” in the

As sem bly / Pre-Operation section of this manual.

TO REPLACE BELTS (See Fig. 21)

The auger and traction drive belts are not adjustable. If the

belts are damaged or begin to slip from wear, they should

be replaced. It is recommended that the belt(s) be replaced

by a Sears service centre/department.

NOTE:

It is recommended that both the auger and traction

drive belt be replaced at the same time.

The V-belts on your snow thrower are of special con struc tion

and should be replaced by original equipment man u fac tur er

(OEM) belts avail able from your nearest Sears service

centre/department. Using other than OEM belts can cause

personal injury or damage to the snow thrower.

WARNING: Belt replacement requires

separation of the snow thrower. While

separating the auger housing from the

frame assembly, it is important that

an assistant stand in the operating

po si tion and hold the snow thrower

han dles. Serious personal injury and/

or damage to the unit could occur if

the snow thrower should fall during

the belt chang ing process.

1. REMOVE GASOLINE FROM FUEL TANK - Drain

gasoline from fuel tank into a suitable container, out-

doors, away from fire or flame. Wipe up any spilled

gasoline.

2. REMOVE DISCHARGE CHUTE - Loosen locknut

se cur ing chute rotator head to mounting bracket only

enough to allow chute rotator head to be raised and

dis charge chute to be removed from snow thrower.

3. REMOVE BELT COVER - See “TO REMOVE BELT

COVER” in this section of this manual.

4. REMOVE ENGINE PULLEY - Remove bolt, flat washer

securing pulley to engine crankshaft. Remove outside

(auger) pulley only from crank shaft.

5. SEPARATE SNOW THROWER - With your assistant

standing in the operating position holding the handles,

re move the two (2) bolts holding the auger housing

and frame together.

WARNING: As the last bolt is removed,

have your assistant carefully lower the

han dles down to the ground.

6. REMOVE HAIRPIN FROM CLUTCH ROD and re-

move clutch rod from swing plate. Tip swing plate

forward.

7. REMOVE AUGER BELT from around pulley.

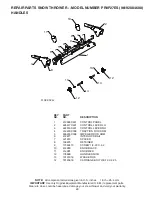

FRAME

ASSEMBLY

AUGER

HOUS ING

HANDLES

FIG. 21

BELT KEEPER

IDLER ARM

SQUARE

HOLE

BOLTS

TRACTION DRIVE BELT

CLUTCHING

IDLER ARM

BRACKET

AUGER

BELT

FLAT WASHER

AUGER PULLEY

AUGER

HOUSING

FRAME

ENGINE

PULLEY

BOLT