-- 7 --

OPERATION

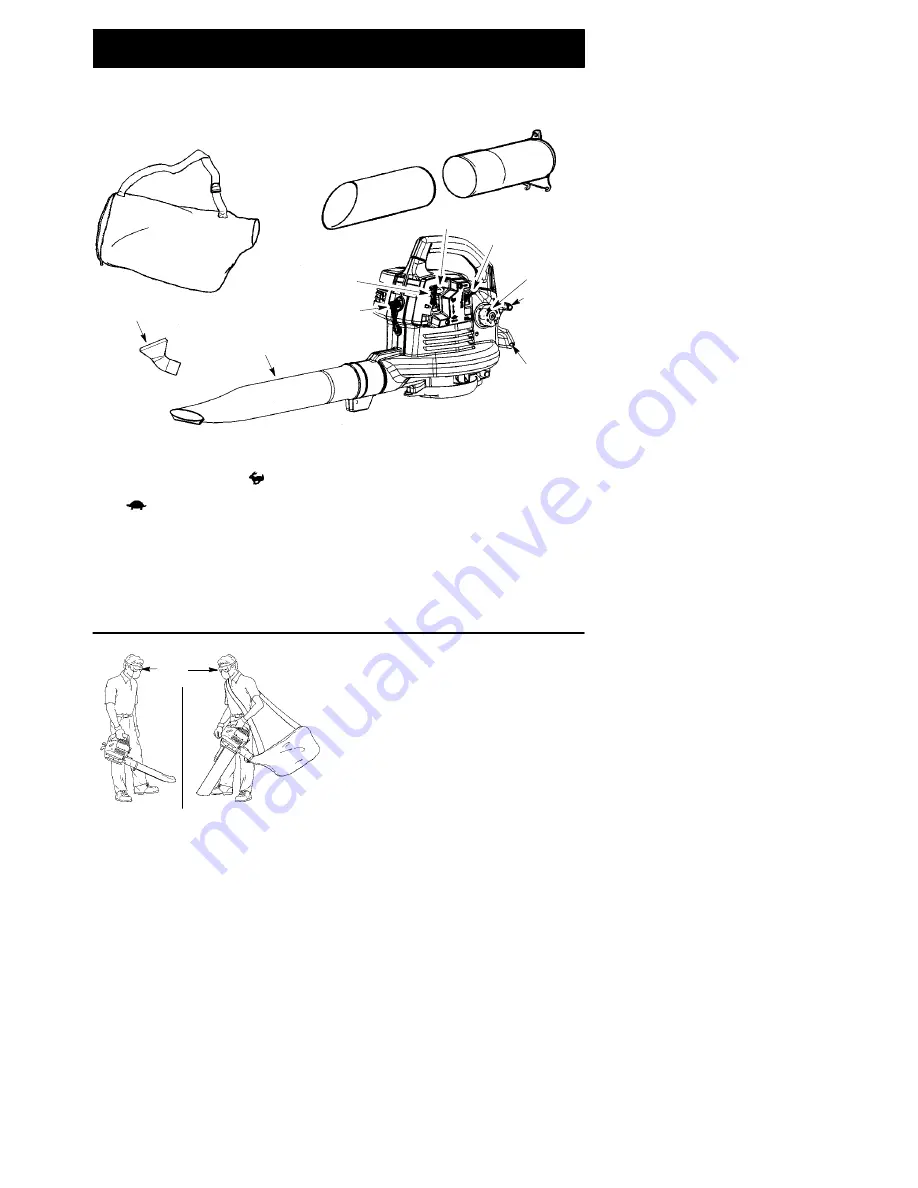

KNOW YOUR BLOWER

READ THIS INSTRUCTION MANUAL AND SAFETY RULES BEFORE OPERATING YOUR UNIT.

Compare the illustrations with your unit to familiarize yourself with the location of the various controls

and adjustments. Save this manual for future reference.

Choke Lever

Fuel Mix

Fill Cap

Starter

Rope

Throttle

Lever

Spark Plug

Blower

Tube

Primer Button

Rear

Handle

Lower

Vacuum Tube

Upper

Vacuum Tube

Vacuum Bag

Elbow Tube

THROTTLE LEVER

The THROTTLE LEVER is used to select the

desired engine speed and to stop the engine.

Move the throttle lever to the

position for

full speed operation. Move the throttle lever

to the

position for idle speed. To stop the

engine, move the throttle lever to the STOP

position.

PRIMER BUTTON

The PRIMER BUTTON removes air from the

carburetor and fuel lines and fills them with fuel.

This allows you to start the engine with fewer

pulls on the starter rope. Activate primer button

by pressing it and allowing it to return to its origi-

nal position.

CHOKE LEVER

The CHOKE helps to supply fuel to the engine

to aid in cold starting. Activate the choke by

moving the choke lever to the FULL CHOKE

position. After engine attempts to start, move the

choke lever to the HALF CHOKE position.

Once engine starts, move choke lever to the

RUN position.

OPERATING POSITION

Blower

Eye

Protection

Vacuum

OPERATING TIPS

S

While vacuuming or blowing debris, hold

the unit with the muffler side facing away

from your body and clothes (see OPERAT-

ING POSITION illustration above).

S

To reduce the risk of hearing loss

associated with sound level(s), hearing

protection is required.

S

To reduce the risk of injury associated with

contacting rotating parts, stop the engine be-

fore installing or removing attachments. Do

not operate without guard(s) in place.

S

Operate power equipment only at reasonable

hours--not early in the morning or late at night

when people might be disturbed. Comply with

times listed in local ordinances. Usual recom-

mendations are 9:00 a.m. to 5:00 p.m.,

Monday though Saturday.

S

To reduce noise levels, limit the number of

pieces of equipment used at any one time.

S

To reduce noise levels, operate power

blowers at the lowest possible throttle

speed to do the job.

S

Use rakes and brooms to loosen debris be-

fore blowing.