5

KICKBACK SAFETY FEATURES

WARNING:

The following features

are included on your saw to help reduce the

hazard of kickback; however, such features

will not totally eliminate this danger. As a

chain saw user, do not rely only on safety de-

vices. You must follow all safety precau-

tions, instructions, and maintenance in this

manual to help avoid kickback and other

forces which can result in serious injury.

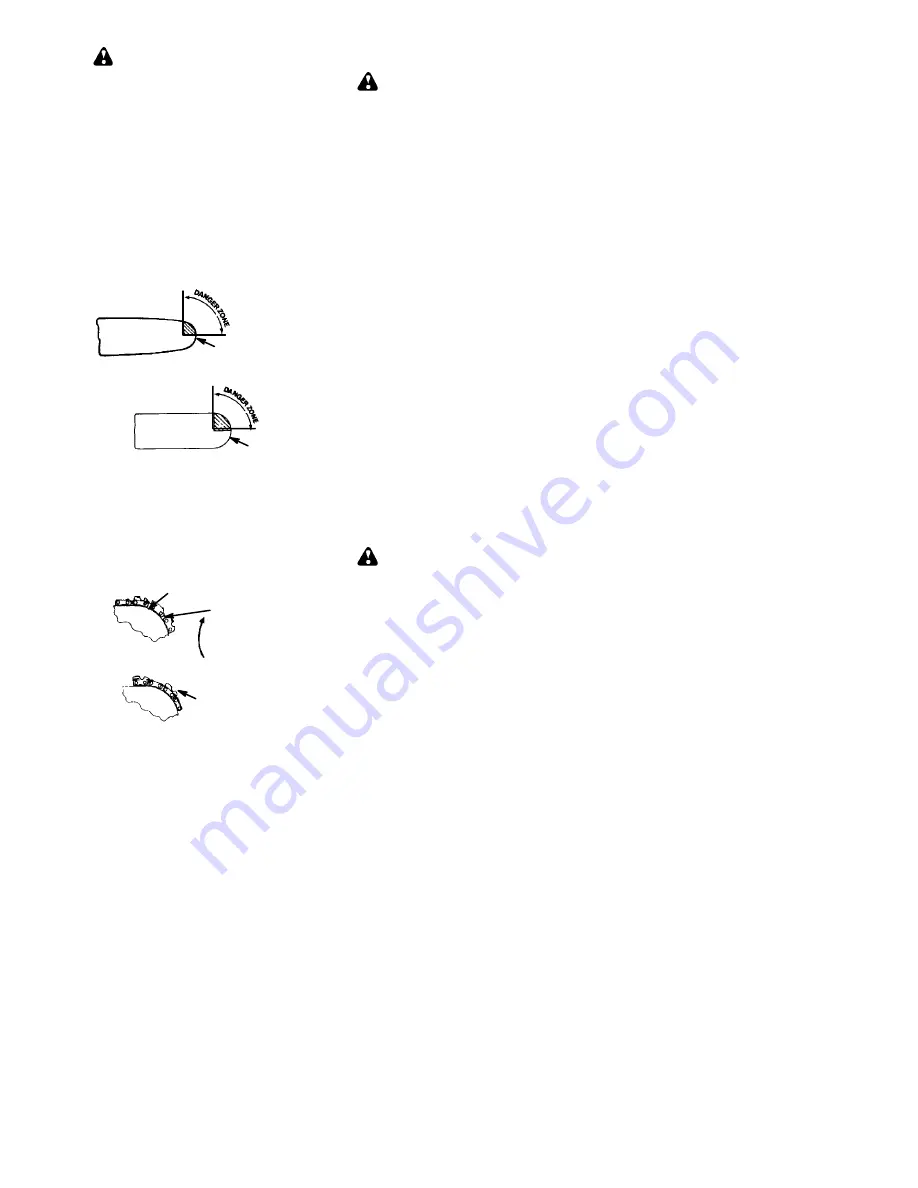

S

Reduced--Kickback Guide Bar, designed

with a small radius tip which reduces the

size of the kickback danger zone on the

bar tip. A Reduced--Kickback Guide Bar

has been demonstrated to significantly re-

duce the number and seriousness of kick-

backs when tested in accordance with

safety requirements for gasoline powered

chain saws as set by ANSI B175.1.

Small Radius Tip

Reduced Kickback Symmetrical Guide Bar

Symmetrical Guide Bar

Large Radius Tip

S

Low--Kickback Chain, designed with a

contoured depth gauge and guard link

which deflect kickback force and allow

wood to gradually ride into the cutter. Low--

Kickback Chain has met kickback per-

formance requirements when tested on a

representative sample of chain saws be-

low 3.8 cubic inch displacement specified

in ANSI B175.1.

Low--- Kickback

Chain

Not a Low--- Kickback Chain

Can Obstruct Material

Contoured Depth Gauge

Elongated Guard Link

Deflects

kickback force

and allows wood

to gradually ride

into cutter

S

Front Hand Guard, designed to reduce the

chance of your left hand contacting the chain

if your hand slips off the front handlebar.

S

Position of front and rear handlebars, de-

signed with distance between handles and

“in-line” with each other. The spread and

“in-line” position of the hands provided by

this design work together to give balance

and resistance in controlling the pivot of

the saw back toward the operator if kick-

back occurs.

CHAIN BRAKE AND CKA ANGLE

S

Chain Brake, designed to stop the chain in

the event of kickback.

WARNING:

WE DO NOT REP-

RESENT AND YOU SHOULD NOT AS-

SUME THAT THE CHAIN BRAKE WILL

PROTECT YOU IN THE EVENT OF A KICK-

BACK. Kickback is a lightning fast action

which throws the bar and rotating chain back

and up toward the operator. Kickback can be

caused by allowing contact of the bar tip in the

danger zone with any hard object. Kickback

can also be caused by pinching the saw chain

along the top of the guide bar. This action may

push the guide bar rapidly back toward the op-

erator. Either of these events may cause you

to lose control of the saw which could result in

serious injury or even death. DO NOT RELY

UPON ANY OF THE DEVICES BUILT INTO

YOUR SAW. YOU SHOULD USE THE SAW

PROPERLY AND CAREFULLY TO AVOID

KICKBACK. Reduced--kickback guide bars

and low--kickback saw chains reduce the

chance and magnitude of kickback and are

recommended. Your saw has a low kickback

chain and bar as original equipment. Repairs

on a chain brake should be made by an autho-

rized servicing dealer. Take your unit to the

place of purchase if purchased from a servic-

ing dealer, or to the nearest authorized master

service dealer.

S

Tip contact in some cases may cause a light-

ning fast reverse REACTION, kicking guide

bar up and back toward operator.

S

Pinching the saw chain along the top of the

guide bar may push the guide bar rapidly

back toward the operator.

S

Either of these reactions may cause you to

lose control of the saw which could result in

serious injury. Do not rely exclusively upon

devices built into your saw.

WARNING:

Computed kickback

angle (CKA) listed on your saw and listed in the

CKA table below represents angle of kickback

your bar and chain combinations will have

when tested in accordance with CSA (Cana-

dian Standards Association) and ANSI stan-

dards. When purchasing replacement bar and

chain, considerations should be given to the

lower CKA values. Lower CKA values repre-

sent safer angles to the user, higher values in-

dicate more angle and higher kick energies.

Computed angles represented indicate total

energy and angle associated without activation

of the chain brake during kickback. Activated

angle represents chain stopping time relative to

activation angle of chain break and resulting

kick angle of saw. In all cases lower CKA val-

ues represent a safer operating environment

for the user.

The following guide bar and chain combina-

tions meet kickback requirements of CSA

Standards Z62.1, Z62.3, & ANSI B175.1 when

used on saws listed in this manual. Use of bar

and chain combinations other than those listed

is not recommended and may not meet the

CKA requirements per standard.