31

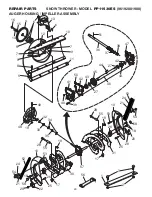

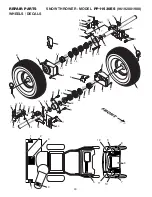

KEY PART

NO. NO.

DESCRIPTION

1 196752X421 Wheel Assembly, 16", Power Steering, LH

2 155443

Pin, Klik 1/4

3 405161

Cover, Power Steering

4 184471

Screw, Hex Head #10-24 x 1/2

5 17060410

Screw

7 17000616

Capscrew, Hex Head, Flanged 1/4-20 x 1/16

8 410294X479 Bracket, Steering Cable, RH

9 410293X479 Bracket, Steering Cable, LH

10 17600406

Screw, Hex Head 1/4-20 x 1/2

11 17490508

Screw, Hex Head 5/16-18 x 1/2

12 405077

Link, Steering Lever

13 193506X479 Yoke, Steering

14 182015

Pin, Steering Lever

15 194944X008 Bellcrank

16 194939X008 Bracket, LH Steering

17 194943X008 Bracket, RH Steering

18 181847

Pin, Steering Bellcrank

19 85179

Retainer, Hairpin

20 179148X479 Bracket, Steering

21 192126

Driver, Wheel

22 182466

Ring, Wire Retainer

23 187622

Lobe, Wheel

24 194941

Slide, Clutch

25 179139

Spring, Clutch Slide

26 194940

Lobe, Axle

27 189282

Key, Square 1/4 x .875

28 174697

Washer, Thrust (1")

29 179830

Bearing, Axle

30 193885

Spring, Return, Steering Latch

31 196753X421 Wheel Assembly, 16", Power Steering, RH

32 700279

Clip, Retainer

33 12000045

Ring, Retaining

34 146315

Screw, Hex Head, Tapping 5/16-18 x 5/8

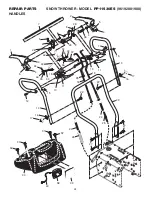

KEY PART

NO. NO.

DESCRIPTION

1 181037

Decal, Danger

2 187867

Decal, Poulan Pro, 11 HP / 30"

3 181035

Decal, Danger, Deflector

4 181042

Decal, Danger

5 187892

Decal, Poulan Pro

6 181033

Decal, Instruction

7 155798

Decal, Traction Lever

8 155800

Decal, Auger Lever

9 181039

Decal, Speed Control

10 183730

Decal, Remote Deflector Control

11 183907

Decal, LH Trigger

12 183905

Decal, RH Trigger

- - 414741

Owner’s Manual, English

- - 414742

Owner’s Manual, French

NOTE:

All component dimensions given in U.S. inches. 1 inch = 25.4 mm

IMPORTANT:

Use only Original Equipment Manufacturer (O.E.M.) replacement parts.

Failure to do so could be hazardous, damage your snow thrower and void your warranty.

REPAIR PARTS

SNOW THROWER - MODEL

PP11530ES

(96192001900)

WHEELS / DECALS