10

4. Push the choke/fast idle lever in to the

HALF CHOKE position.

5. Pull the starter rope quickly with your

right hand until the engine starts.

6. Allow the engine to run for approximately

30 seconds. Then, squeeze and release

throttle trigger to allow engine to return to

idle speed.

ON/STOP SWITCH

CHOKE/FAST IDLE LEVER

FULL HALF OFF

STARTING A WARM ENGINE

1. Move ON/STOP switch to the ON position.

2. Pull the choke/fast idle lever out to the

HALF CHOKE position.

3. Pull the starter rope quickly with your right

hand until the engine starts.

4. Squeeze and release the throttle trigger

to allow engine to return to idle speed.

DIFFICULT STARTING (or starting a

flooded engine)

The engine may be flooded if it has not started

after 10 pulls.

Flooded engines can be cleared of excess fuel

by following the warm engine starting proce-

dure listed above. Ensure the ON/STOP

switch is in the ON position.

Starting could require many pulls depending on

how badly unit is flooded. If engine still fails to

start, refer to TROUBLESHOOTING TABLE

or call 1-800-554-6723.

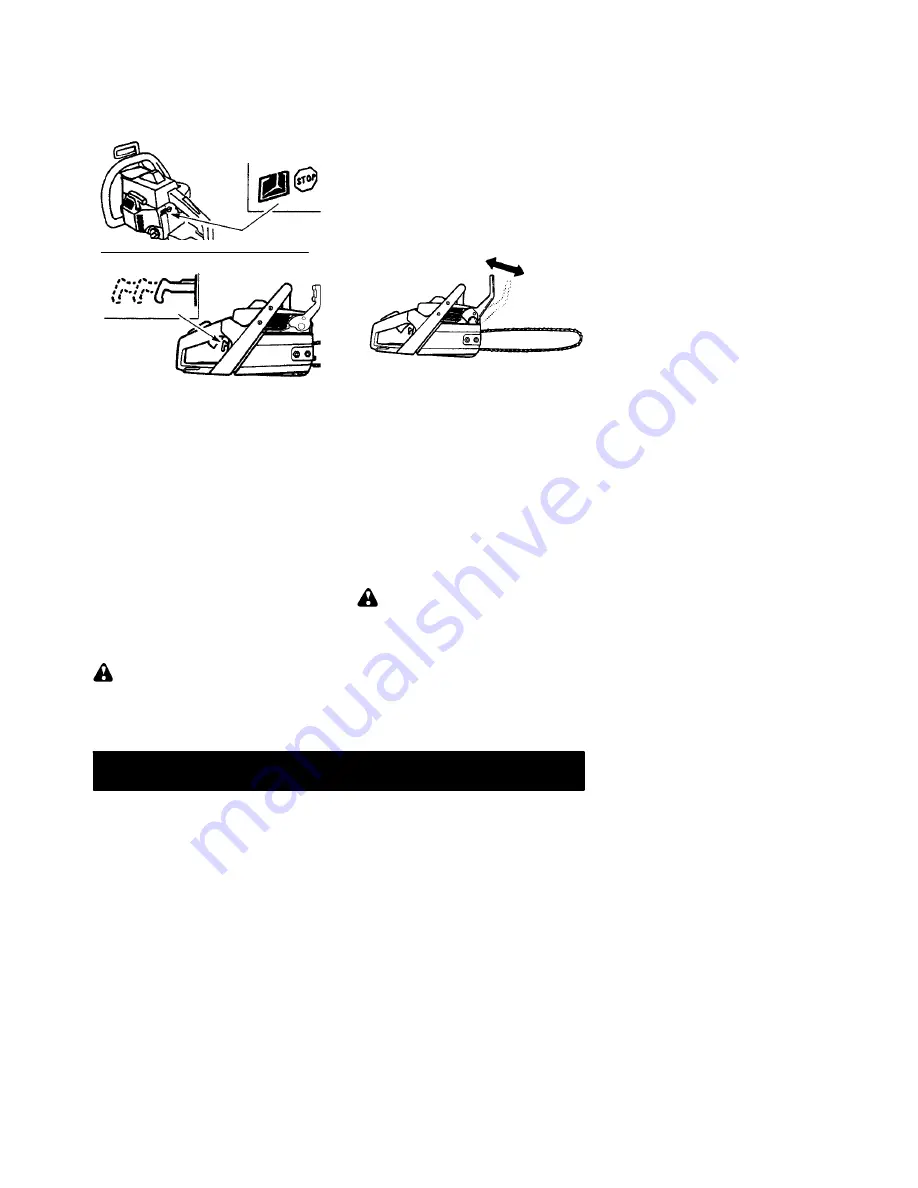

CHAIN BRAKE

WARNING:

If the brake band is worn

too thin it may break when the chain brake is

triggered. With a broken brake band, the chain

brake will not stop the chain. The chain brake

should be replaced by an authorized service

dealer if any part is worn to less than 0.020

″

(0.5 mm) thick. Repairs on a chain brake

should be made by an authorized service deal-

er. Take your unit to the place of purchase if

purchased from a servicing dealer, or to the

nearest authorized master service dealer.

S

This saw is equipped with a chain brake.

The brake is designed to stop the chain if

kickback occurs.

S

The inertia--activated chain brake is

activated if the front hand guard is pushed

forward, either manually (by hand) or

automatically (by sudden movement).

S

If the brake is already activated, it is

disengaged by pulling the front hand guard

back toward the front handle as far as

possible.

S

When cutting with the saw, the chain brake

must be disengaged.

Disengaged

Engaged

Braking function control

CAUTION:

The chain brake must be

checked several times daily. The engine must

be running when performing this procedure.

This is the only instance when the saw should

be placed on the ground with the engine run-

ning.

Place the saw on firm ground. Grip the rear

handle with your right hand and the front han-

dle with your left hand. Apply full throttle by

fully depressing the throttle trigger. Activate

the chain brake by turning your left wrist

against the hand guard without releasing

your grip around the front handle. The chain

should stop immediately.

Inertia activating function control

WARNING:

When performing the

following procedure, the engine must be

turned off.

Grip the rear handle with your right hand and

the front handle with your left hand. Hold the

chain saw approximately 14

″

(35 cm) above

a stump or other wooden surface. Release

your grip on the front handle and use the

weight of the saw to let the top of the guide

bar fall forward and contact the stump.

When the tip of the bar hits the stump, the

brake should activate.

CUTTING METHODS

IMPORTANT POINTS

S

Check chain tension before first use and

after 1 minute of operation. See CHAIN

TENSION in the ASSEMBLY section.

S

Cut wood only. Do not cut metal, plastics,

masonry, non-wood building materials,

etc.

S

Stop the saw if the chain strikes a foreign

object. Inspect the saw and repair or re-

place parts as necessary.

S

Keep the chain out of dirt and sand. Even a

small amount of dirt will quickly dull a chain

and thus increase the possibility of kickback.