Powered by Safety

®

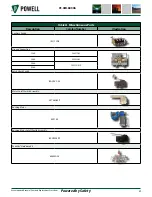

45

Maintenance

01.4IB.60306

4) Slow Closing of Mechanism

The slow closing of mechanism described

is not required for routine maintenance;

however, it may be a useful procedure

for troubleshooting circuit breaker

misoperation.

a. With the main closing spring assembly

removed, rotate the camshaft so that

the crank arms are pointing downward.

The fundamental linkage will now move

into the reset position.

b. Push the manual close operator inward

and hold it in while operating the

charging handle to rotate the camshaft.

c. When the close release latch arm has

passed the close shaft latch plate, the

manual close operator may be released.

As the main closing cam engages

the main cam roller, the jackshaft will

commence to rotate.

d. Continue to operate the charging

handle until the crank arms point

upward. The circuit breaker will now be

closed and there will be a gap between

the operating pushrod lock nuts and

the pivot blocks.

e. Return the circuit breaker to the open

position by depressing the manual trip

operator.

f. To install the main closing spring

assembly reverse the preceding removal

procedure.

5) Mechanism Adjustments

Several factory adjustments in the stored

energy mechanism are described in this

section. NO ADJUSTMENT OF THESE

SETTINGS IS REQUIRED FOR ROUTINE

MAINTENANCE, but they may need to be

adjusted after a major overhaul or removal

of the mechanism.

CAUTION

Do NOT adjust these settings unnecessarily as

damage to the circuit breaker may occur.

a. Adjustment of Ratchet Wheel Holding

Pawl

The holding pawl support arm

) is adjusted by the holding

pawl adjusting eccentric (

If the pawl is not properly adjusted,

there will be a “knocking” noise when

the ratchet mechanism is operating or

the stored energy mechanism will not

ratchet at all.

To adjust the pawl perform the

following steps:

1. Remove the escutcheon to gain

access to the head of the bolt

holding the adjusting eccentric.

2. Loosen the bolt slightly.

3. Grip the eccentric with a pair of

slip-joint pliers or a similar tool and

rotate the stop slightly.

4. Tighten the holding bolt with the

eccentric in the new position.

5. While charging the main closing

springs, using the charging motor

to drive the mechanism, observe

the ratcheting operation for

improvement.

6. If the ratcheting operation has not

improved, repeat the preceding

sequence until the ratcheting

operation is smooth. This may

require several charging cycles.