Powered by Safety

®

16

Equipment Description

PowlVac® ARG & ARM Series 4 Vacuum Circuit Breakers

5kV & 15kV - 1200A, 2000A, & 3000A - 25kA, 36kA, 50kA, & 63kA

01.4IB.60306

The close latch, when released either by the

closing coil or the manual close operator,

allows the main closing spring to pull the

crank arms upward thus rotating the main

closing cam and driving the fundamental

linkage into the closed position. This

causes the main linkage to rotate the

jackshaft such that the operating pushrods

(

) are driven toward the

current carrying side of the circuit breaker.

Each operating pushrod assembly has a

recess at each end which encloses a contact

loading spring (

). At the end

of this spring is a spring yoke (

), which connects with bell cranks. The

spring yoke is restrained by a lock nut on

a stud which passes through the contact

loading spring and is attached to the

operating pushrod assembly. The contact

loading spring has initial compression such

that as soon as the vacuum interrupter

contacts touch, the springs are preloaded

to a value sufficient to resist vacuum

interrupter contact separation under the

highest electromagnetic forces exerted

by the rated short circuit current. Further

movement of the operating pushrod

assembly compresses the contact loading

spring even more and produces a gap

between the face of the spring yoke

and the lock nut. This “nut gap” is used

to evaluate the erosion of the vacuum

interrupter contacts.

For each phase, bell cranks (

are located on the outside of the lower

primary disconnecting devices

(

) and are supported by bearings.

Each bell crank is connected to an

operating pin, which passes through a slot

in the lower primary disconnecting devices

and engage an extension to the vacuum

interrupter assembly thus moving the

vacuum interrupter contact. The bell cranks

give an approximate 3 to 1 multiplication

of the contact loading spring force,

enabling a lower spring rate to be used.

It also multiplies the contact movement

by a factor of approximately 3, so that the

mechanism linkages have relatively large

movements and are less critical.

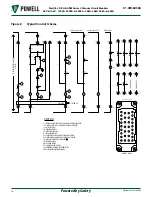

In the cam and fundamental linkage

positions (

), the contact loading

springs and the main opening springs are

both acting to compress the three (3) main

mechanism links. The jackshaft extends

from the left to the right side of the circuit

breaker frame and is supported at the

main circuit breaker frame side sheets and

by the mechanism side sheets. The outer

operating levers on the jackshaft have

connections to the circuit breaker opening

springs (

).

The fundamental linkage is restrained from

movement by the secondary trip prop

acting on the primary trip prop roller. A

component of force tends to make the

primary trip prop rotate upward, but it

is restrained by the secondary trip prop

face acting on the primary trip prop roller.

The clearance between the primary trip

prop roller and the secondary trip prop

is controlled by the primary trip prop

adjusting screw. When the trip shaft is

rotated by the action of the manual trip

operator or the primary shunt trip coil, the

secondary trip prop face moves downward

and permits the primary trip prop to rotate

upward, thus permitting the main linkage

to move upward and the jackshaft to

rotate, opening the circuit breaker. The left

jackshaft levers engage a shock absorber

), which controls the rebound

of the vacuum interrupter contacts on an

opening operation. An extension of the

jackshaft projects through the left circuit

breaker side sheet and operates the MOC

actuator (

).