Powered by Safety

®

10

Equipment Description

Power/Vac

®

Metal-Clad Switchgear 5kV & 15kV

01.4IB.67000

e. B

reAker

l

Ift

t

ruck

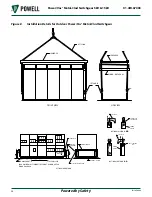

For ease of breaker handling during installation

and removal, a breaker lift truck is furnished

as a standard accessory with each

Power/Vac switchgear order. This accessory

device is used to elevate the breaker from

the floor or working platform to the level of

the tracks in the switchgear compartment.

Docking of the lifting device rails to the

switchgear tracks is provided for maximum

safety. Refer to

the Removable Element into the Compartment

or the latest version of Instruction Bulletin

01.4IB.66000.

f. r

AtInGS

Ratings of Power/Vac switchgear and circuit

breakers are based on factors supplied in the

following:

• ANSI C37.04 Circuit Breaker Rating

Structure

• ANSI C37.06 Circuit Breaker Ratings

• ANSI C37.20.2 Switchgear Assemblies

See

Table B, Ratings of Medium Voltage

Power/Vac® Metal-Clad Switchgear

for complete

ratings.

Note:

Certain non-standard ratings are

available for special applications.

Consult the manufacturer for details.

Refer to the specific job drawings for

detailed voltage ratings applicable to

particular switchgear line-up.

G. l

IGhtInG

I

mpulSe

W

IthStAnd

(BIl)

The basic impulse level is 60kV for the 4.16kV

class switchgear and 95kV for the 8.25kV and

13.8kV class switchgear. The basic impulse

level testing excludes control transformers,

starting reactors, and autotransformers.

Note:

If required, AC Field Dielectric Tests

should be limited to 75% of Factory

Dielectric Test values. Direct current

dielectric testing is not recommended.

If DC testing is required, see

Ch 4 Installation, U. Testing and

for values to be used.

h. c

IrcuIt

B

reAker

r

AckInG

m

echAnISm

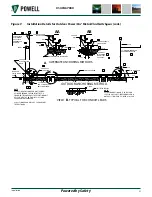

The circuit breaker may be placed in three

distinct positions within the circuit breaker

compartment of the switchgear:

• Disconnected Position

• Test Position

• Connected Position

In the “disconnected position” the movable

primary disconnects of the circuit breaker are

disengaged and separated at a safe distance

from the stationary primary disconnecting

devices located in the compartment. A metal

shutter covers the openings of the stationary

primary disconnecting devices which prevents

contact. In this position, the secondary

disconnect devices and control contacts are

disengaged.

In the “test position”, the primary disconnecting

devices are disengaged and the shutters are

closed. The secondary circuits are completed

by inserting the secondary disconnect plug

(breaker) into the secondary disconnect

receptacle of the switchgear compartment via

the breaker mounted handle. Now the circuit

breaker may be electrically operated without

affecting the primary circuit.