Powered by Safety

®

26

Installation

Power/Vac

®

Metal-Clad Switchgear 5kV & 15kV

01.4IB.67000

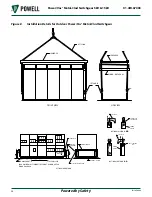

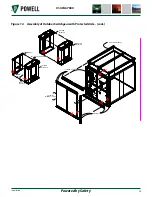

2) Outdoor Metal-Clad Switchgear

Switchgear support should be concrete

or reinforced concrete with depth, fill,

drainage, etc., according to recommended

foundation design for the loading, type of

construction, and local conditions involved.

The base furnished with the switchgear

should be supported on a level surface

over the full area of the switchgear. Steel

supporting members should be furnished

if required for leveling the foundation

and supporting the switchgear. Refer to

for recommended foundation and

anchoring.

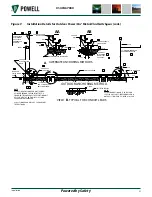

Primary and secondary conduits should be

installed in accordance with the requisition

drawings, before the equipment is put into

place. Conduits must extend no more than

one inch above the finished floor prior to

the installation of the switchgear.

When outdoor pieces of equipment are

shipped in more than one section, the

roof joint between the sections must be

assembled as shown in

. Shipping

sections must be assembled in the proper

sequence due to the location of conduits.

The left hand section of a switchgear lineup

must be positioned in its final location first.

Then the section located immediately to

the right must be positioned as close as the

lifting members permit with the front in

alignment with the first section. Remove

the lifting members and then push or jack

the unit to the left until it is flush with the

first section.

!

CAUTION

Be sure to distribute the forces over the

side frame using appropriate timbers so as

not to deform or damage the surface of the

structure.

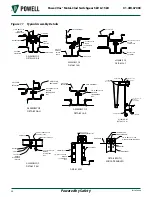

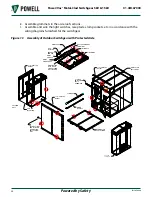

3) Outdoor Switchgear with Protected Aisle

a. Remove aisle front wall from the front

of the metal-clad switchgear, discard

all yellow shipping covers on aisle wall

and front of metal-clad switchgear

except lifting members. Reuse 3/8

- 16 hardware. Since the relay and

instrument cases are not weatherproof,

the control panels should be protected

from inclement weather until the

installation of the aisle enclosure is

complete.

b. Lay down aisle floor in front of each

metal-clad unit

. Secure at

each unit line with tie plate and floor

cap per

. Secure to

metal-clad per

c. For aisle end wall design, disassemble

channel cap, cap bushing, roof cap,

end trim, and corner cap. Reassemble

at end of aisle that has the aisle end

wall. Reuse 1/4 - 20 hardware and plug

buttons.

d. Disassemble aisle end extensions

or aisle end extension and aisle end

wall

. Do not

remove shipping support from aisle end

wall.

e. Position aisle end extension(s) and/or

aisle end wall(s) at ends of the line-up.

Secure aisle extension to aisle floor and

metal-clad switchgear

. Secure aisle end wall per

.

f. Set up aisle wall and secure to aisle

floor, aisle end extension(s), aisle end

wall(s) and shipping split.

and

.

g. Apply prestite gasketing material to the

top of aisle wall, metal-clad roof, and

aisle end wall. Punch holes in gasket

with drift pin.