Powered by Safety

®

27

Installation

01.4IB.67000

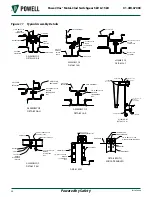

h. Remove roof angle (reuse 1/4 - 20

hardware) and set aisle roofs in place,

taking care to align the lap joint

between the aisle and switchgear roof

assemblies before contacting prestite

gasket. Secure roof sections to each

other, to aisle wall and metal-clad

switchgear per

i. Apply RTV clear seal and assemble roof

caps, cap bushings, and channel end

caps.

Figure 11, details L & M, P & N

.

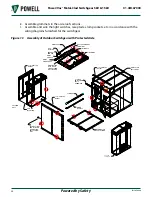

j. After steel erection is complete,

check to certify that all bolted, butt,

or overlapped joints are resistant to

water leaks. A source of outside light

in a darkened aisle is an indication that

RTV108 clear seal should be applied to

the exterior surfaces.

k. Assemble grommets in the aisle roof

sections.

l. Assemble and wire the light switches,

receptacles, lamp sockets, etc. in

accordance with the wiring diagrams

furnished with the equipment.

m. Anchor the base of the protected aisle

assembly to the concrete pad using the

anchor clips provided. Install anchor

bolts in accordance with the requisition

drawing.

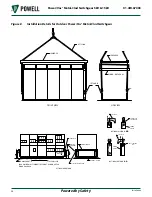

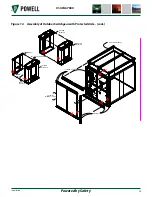

4) Outdoor Switchgear with Common Aisle

a. Remove and discard the yellow

shipping covers on front of

metal-clad switchgear. Since the

relay and instrument panels are not

weatherproof, the control panel should

be protected from inclement weather

until the installation of the aisle

enclosure is completed.

b. Lay down aisle floor in front of each

metal-clad unit of first switchgear

line-up. Secure to metal-clad per

.

c. Move second switchgear line-up into

position and secure to aisle floor per

. After the switchgear is

secured to the aisle floor, it should be

anchored to the concrete pad using the

anchor clips provided. Install anchor

bolts in accordance with the requisition

drawing.

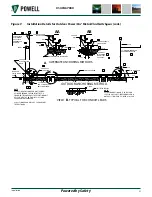

d. For aisle end wall design, disassemble

channel cap, cap bushing, roof cap,

end trim, and corner cap. Reassemble

at end of aisle that has the aisle end

wall. Reuse 1/4 - 20 hardware and plug

buttons.

e. Disassemble aisle end extensions

or aisle end

extension and aisle end wall.

. Do not remove

shipping support from aisle end wall.

f. Position aisle end extension(s) and/or

aisle end wall(s) at ends of the lineup.

Secure aisle extension to aisle floor and

metal-clad switchgear

. Secure aisle end wall per

.

g. Apply prestite gasketing material to top

of metal-clad roof and aisle end wall.

Punch holes in gasket with drift pin.

h. Remove roof angle (reuse 1/4 - 20

hardware) and set aisle roofs in place

taking care to align the lap joint

between the aisle and switchgear roof

assemblies before contacting prestite

gasket. Secure roof sections to each

other and to metal-clad switchgear per

Figure 11, details R, L & M, P & N

.

i. Apply RTV clear seal and assemble roof

caps, cap bushing, and channel end

caps.

j. After steel erection is complete,

check to certify that all bolted, butt

or overlapped joints are resistant to

water leaks. A source of outside light

in a darkened aisle is an indication that

RTV108 clear seal should be applied to

the exterior surfaces.