Powered by Safety

®

39

Installation

01.4IB.67000

insulated before the operating voltage

is applied.

Note:

All hardware must be tightened to the

torque values listed in

Torque Values for Power/Vac® Medium

.

2) Sliding Connections

a. Stationary Primary Disconnect Devices

- Breakers and Rollouts

Wipe contact surfaces with a clean, soft,

dry, lint-free cloth to remove dirt and

grease from silvered areas. Do not use

any abrasives such as sand paper, emery

cloth or steel wool for this purpose.

Avoid handling of the contact surfaces

after cleaning. Apply a thin coat of

Mobil grease (Red) to the front two

inches of all breaker and rollout primary

disconnect devices. Cover all surfaces,

front, sides, top and bottom evenly.

b. Stationary Ground Contact Cluster

Prepare the contact surfaces as

described in the previous section

a. Stationary Primary Disconnect Devices,

giving special

attention to the facing curved surfaces

to be sure no sharp edges or burrs exist

at the narrowest dimension. Apply a

thin coat of Mobil grease (Red) to the

facing curved surfaces for a distance of

no less than 3/4 inch centered around

the point of narrowest dimensions.

c. Movable Primary Disconnect Devices -

Rollouts

Before assembling the contact fingers,

prepare the contact surfaces (double

thickness segment) of the primary tangs

and apply a thin coat of Mobil grease

(Red) as described in section

a. Stationary Primary Disconnect Devices

. Assemble and

pin the contact fingers in place. Apply

a thin coat of Mobil grease (Red) to the

facing curved surfaces of the contact

fingers as described in section

.

m. m

AIn

B

uS

A

SSemBly

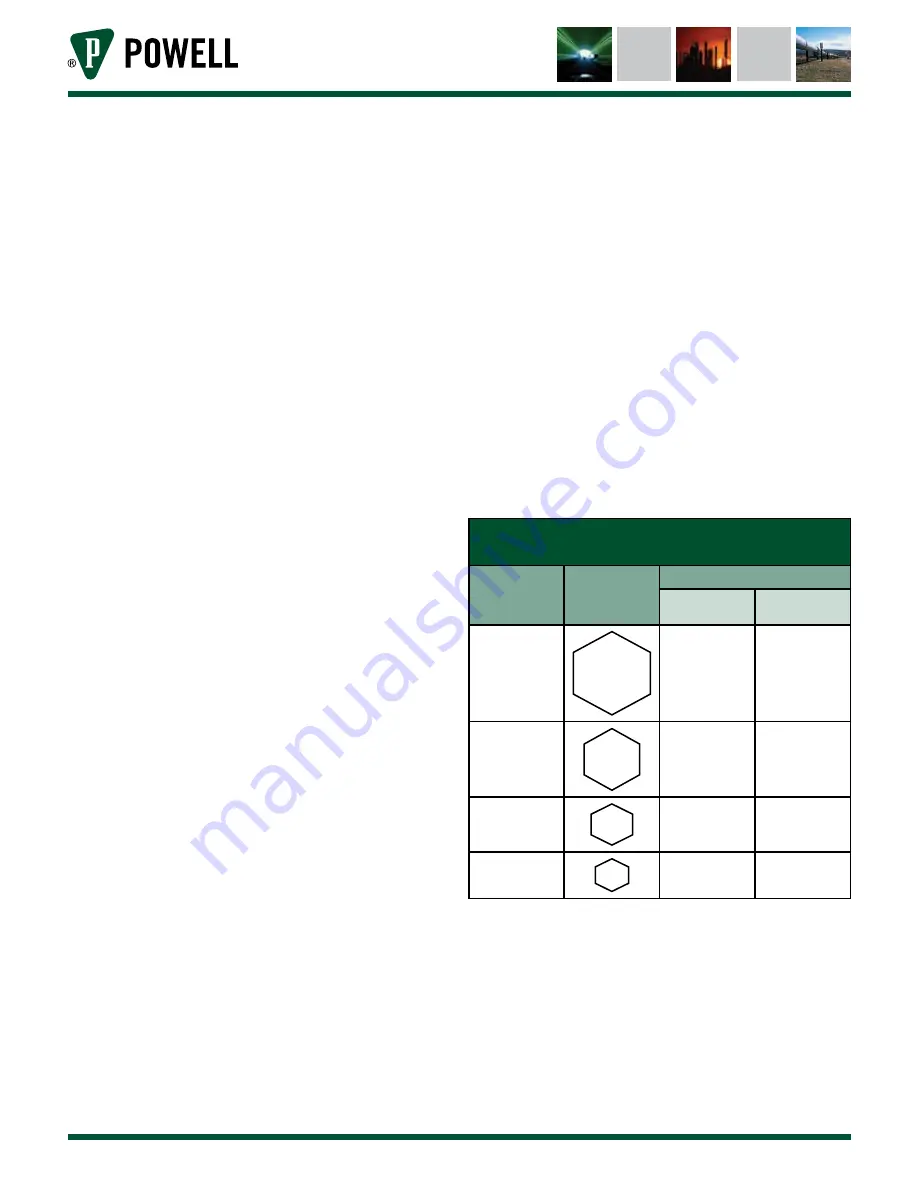

Table C Bolt Torque Values for Power/Vac

®

Medium Voltage Metal-Clad Switchgear

Bolt

Dimensions

(inches)

Bolt

Head

Torque

Ft-Lbs

Kg-M

5/8

55-70

7.6-9.7

1/2

35-50

4.8-6.9

3/8

20-30

2.8-4.2

1/4

5-7

0.7-0.97