Powered by Safety

®

1

General Information

01.4IB.51000C

Ch 1 General Information

!

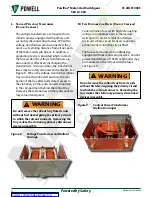

WARNING

The equipment described in this document may contain high voltages and currents which can

cause death or serious injury.

The equipment is designed for use, installation, and maintenance by knowledgeable users of such

equipment having experience and training in the field of high voltage electricity. This document and all

other documentation shall be fully read, understood, and all warnings and cautions shall be abided by. If

there are any discrepancies or questions, the user shall contact Powell immediately at 1.800.480.7273.

!

WARNING

Prior to adjustments, servicing, maintenance, or any act requiring the operator to make physical

contact with the equipment, the power source must be disconnected and the equipment grounded.

Failure to do so may result in death or serious injury.

NOTICE

The information in this instruction bulletin is not intended to explain all details or variations of the

Powell equipment, nor to provide for every possible contingency or hazard to be met in connection

with installation, testing, operation, and maintenance of the equipment. For additional

information and instructions for particular problems, which are not presented sufficiently for the

user’s purposes, contact Powell at 1.800.480.7273.

Powell reserves the right to discontinue and to change specifications at any time without incurring

any obligation to incorporate new features in products previously sold.

NOTICE