Powered by Safety

®

19

Installation

01.4IB.51000C

3. The auxiliary control devices, ship loose

material and protective relays must also

be protected. This includes items such as

battery chargers, UPS systems, lighting,

installation hardware and air conditioning.

If prolonged storage is anticipated,

humidity controlling desiccant materials

should be utilized. Desiccant packets

should be installed in all compartments and

packing containers.

e. p

repArAtIon

of

f

loor

-A

nchorInG

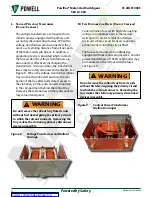

The station floor must be strong enough to

remain rigid and not sag under the weight of

the switchgear structure. The floor also must

be able to withstand the impact stress caused

by the opening of the circuit breakers under

short-circuit conditions. The short circuit

impact load is approximately 1-1/2 times the

static load weight of the switchgear.

The purchaser must provide suitable means

for anchoring the switchgear to the floor. The

floor supporting the switchgear must be level

in order to avoid distorting the switchgear

structure and to align the switchgear

properly. The switchgear must be correctly

and completely aligned prior to applying final

anchors. Level foundations are desirable since

they automatically produce true, level, and

plumb switchboard installations. However,

the switchgear will operate satisfactorily on

a true and flat foundation that has a uniform

slope of no more than 1/8 inch in three feet.

The switchgear units must be placed on the

floor channels in such a manner that the

base of each unit rests directly on each of

the floor channels. The recommended floor

construction is shown in Figure 11.

The floor channels should have a minimum

web dimension of 4 inches. The required

quantity and location of the floor channels

is shown on the drawings furnished with

the order. The spacing of the floor channels,

including the center channel, must be as

shown on the drawings. Even though the

switchgear is not anchored to the center

channel, its location is important to the proper

support and alignment of the switchgear units.

The floor channels must be level and straight

with respect to each other. Brass shims should

be placed under floor channels when leveling

is needed.

Care should be taken to provide a smooth,

hard, and level floor surface in front of the units

to facilitate installation and removal of the

circuit breakers. The floor in front of the circuit

breaker compartments should be level with,

or slightly below, the base of the switchgear

to facilitate inserting and withdrawing the

circuit breakers. The step up from the floor into

the circuit breaker compartment should be

no more than the two metal thicknesses that

make up the compartment floor and breaker

pan. Critical components on the circuit breaker

may be damaged if the step is larger. Should

there be a gap between the concrete floor and

the top of the floor leveling channel at the

front of the lineup, the floor must be leveled

relative to the circuit breaker compartments

for approximately 36” extending away from the

switchgear. This will assure the circuit breaker

enters its compartment with a step up of no

more than 1/4”.

When installing the switchgear on existing

floors, it is recommended to pour a new finish

floor with embedded channels, or to cut slots

in the floor for embedding and leveling the

supporting channels.