Powered by Safety

®

24

Installation

01.4IB.51000C

PowlVac® Metal-Clad Switchgear

5kV & 15kV

J. c

onnectIonS

The main bus bars and other connection bars

are copper. The connection surfaces are silver

surfaced or equivalent. The silver plating used

on bolted contact surfaces is approximately

0.0001” thick. All field assembled joints in

primary conductors, regardless of method of

installation, should be made as follows:

1. Wipe the surface clean with a lint free cloth.

Do not use sandpaper or any abrasive

on the plated surface. Avoid handling of

cleaned surface as much as possible. If

the surface is tarnished, clean it with silver

polish and then wash it with denatured

alcohol.

2. Join the clean contact surfaces by using the

hardware provided. The correct length of

bolt must be used in each joint to ensure

that electrical clearances at bolt locations

are maintained. As a general rule, when

using ½” diameter bolts, the bolt should be

1” longer than the combined thickness of

the copper bars being bolted together. For

example, if three ¼” thick copper bars are to

be connected, the bolt should be 1¾” long.

In addition to proper length bolts, the bolt

assembly must include flat washers, split

ring lock washers, and nuts. All hardware

must be SAE Grade 5 or better. Refer to

Figure 15 for proper assembly of hardware.

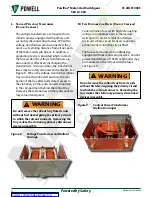

Figure 15 Ground Bus Splice Plate Connection

a

b

c

d

e

a. Bolt

b. Flat Washer

c. Bus Bar

d. Split Lock Washer

e. Nut

!

CAUTION

All exposed primary bus and cable joints and

connections must be insulated to the system

insulation rating.

3. In some cases, external connections are

made to the equipment main bus by bars.

The equipment bars are normally silver

plated. Unplated bars either copper or

aluminum should not be used to connect

to plated bars.

4. All field assembled primary conductor

joints and terminations must be insulated

for the operating voltage. There are two

methods of insulating the joints: Taping

joints or applying boots where applicable.

A detailed procedure for joint insulation

is described in

.

Note:

All hardware must be tightened to the

torque values listed in Table C, Bolt