Powered by Safety

®

20

Maintenance

PowlVac

®

Ground & Test Device 15kV (ConEd EI-4102)

IB-50022A

Ch 6 Maintenance

A. G

ENERAL

A regular maintenance schedule should be

established to obtain the best service and

reliability from the ground and test device. The

ground and test device is designed to require

maintenance every 1000 operations or once a

year, whichever occurs first.

Actual inspection and maintenance will

depend on individual application conditions

such as number of operations, time between

uses, and storage conditions. When the ground

and test device has been in storage for an

extended period of time, it must be inspected

and cleaned before being used. See

Ch 4 Installation,

C. S

TORAGE

and

D. P

REPARING

THE

E

LECTRICALLY

O

PERATED

G

ROUND

AND

T

EST

D

EVICE

FOR

U

SE

.

A permanent record of maintenance work

and inspection should be kept. The degree

of record detail depends on the operating

conditions. The record should include the

dates and results starting from the date the

device is first put into service. Dates and

results of inspections and routine maintenance

activities should be recorded.

B. I

NSPECTION

AND

C

LEANING

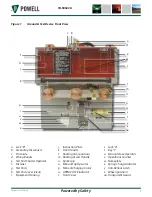

Inspect the ground and test device for loose or

damaged hardware or parts. Tighten any loose

hardware, and replace missing or damaged

hardware or parts.

When necessary, remove loose dust and dirt

from the ground and test device with a vacuum

cleaner, a clean, dry cloth, or an industrial-type

wiper. Do NOT use an air hose to clean the

ground and test device. Dirt or grit may be

blown into critical parts, including bearings,

which cause excessive wear of the parts.

Primary insulation should be cleaned if needed.

Wipe insulation parts clean with a dry lint-free

cloth or an industrial-type wiper. If dirt adheres

and will not come off by wiping, remove it

with distilled water or a mild solvent such as

denatured alcohol. Ensure that the ground

and test device is dry before use. Do NOT use

any type of detergent to wash the surface of

the insulators, as the detergent may leave an

electrical conducting residue on the surface as

it dries.

C. L

UBRICATION

The contact surfaces of the primary disconnect

stabs and the fingers of the ground shoe

should be lubricated with a thin film of

Mobilgrease 28. Before use, particularly if the

ground and test device has been in storage for

a long time, wipe these surfaces with a clean,

dry cloth, and apply fresh lubricant.